Robotics

Pick-by-Robot - smart connection between man and machine for picking processes

Pick-by-Robot is an innovative way to relieve the strain on humans during picking activities - reliably, quickly and without fatigue. A flexible and retrofittable pick-by-robot system provides logistics with a forward-looking alternative to manual picking.

The benefits at a glance

- Reliable and tireless

- 24/7 operation

- Low operating costs

- High picking reliability

- High productivity

- Error-free picking

- Uncomplicated setup and flexible integration into existing picking stations

- Self-learning with AI

- Individual safety concept

All about Pick-By-Robot

What is pick-by-robot?

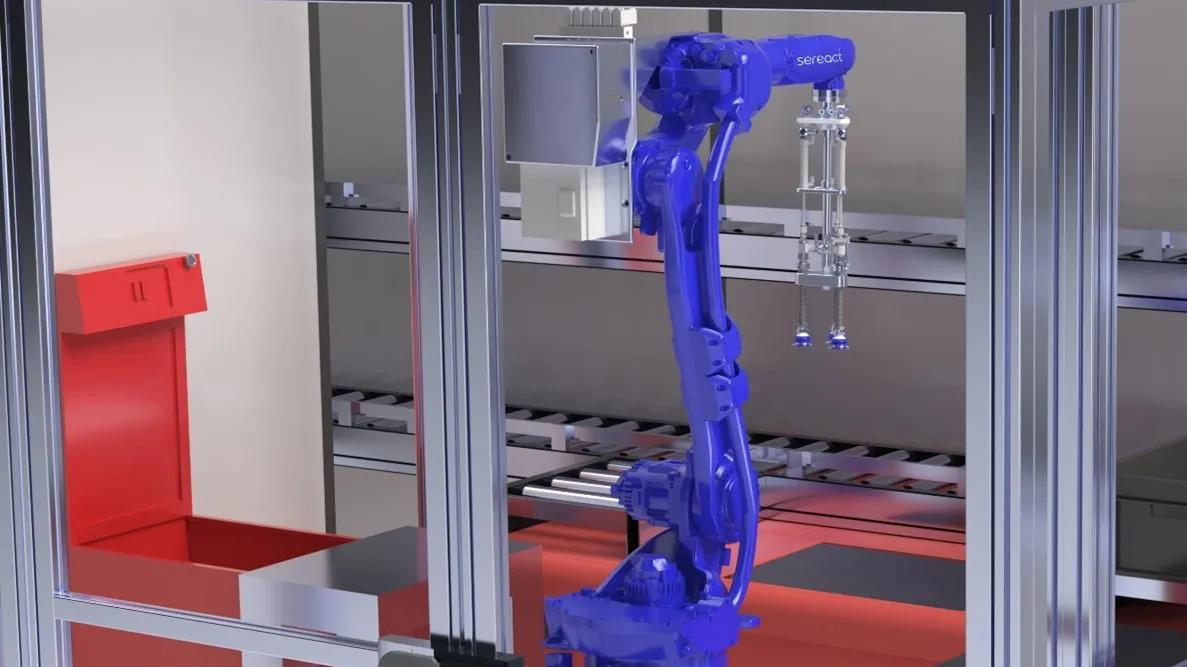

Pick-by-robot is a picking technology for processing picking processes - and it is completely automated. Instead of picker staff, the robot takes over all activities when picking items for one or more orders. Special grippers for small load carriers (SLCs) or individual parts (piece/item picking) can be used to ensure full flexibility

Our partners, integrators & manufacturers

sereact

Embodied AI for robotics: Sereact was founded by Ralf Gulde (CEO) and Marc Tuscher (CTO). The Stuttgart-based total solution provider develops AI-supported robotics solutions that are used in various industries and application areas by leading customers in Europe and the USA. The AI software gives robots visual and motor skills, enabling them to perceive their environment and develop intelligent strategies to perform a variety of physical tasks. From the precise handling of individual objects to the management of complex logistics and manufacturing processes, the systems analyze and solve unknown situations in real time. This enables the detection of anomalies, the optimization of processes and the setting of new standards in flexibility and efficiency for autonomous systems.

For more information, visit the official sereact website.

Bayer Robotics

Bayer GmbH & Co KG from Wörnitz in Franconia is an owner-managed company and has been operating as a flexible industrial partner in the fields of robotics, engineering and 3D measurement with state-of-the-art laser scanning equipment since 1999.

Further information can be found on the official Bayer Tech website.

The solution in detail

To further increase the level of automation in AutoStore small parts warehouses, a picking robot with AI-supported image recognition is installed. This replaces the manual storage and retrieval of items in AutoStore containers.

Instead of the warehouse worker or order picker removing items from the respective container or loading equipment (picking process), pick-by-robot is a fully automated picking method.

The items are picked directly from the container by the swivel arm with the corresponding gripper technology and placed in the target container.

The picking robot receives its picking orders from the higher-level HiLIS warehouse management system.

The hardware of a pick-by-robot system consists of a flexible swivel arm with a suction head or SLC gripper and a vision module. With mechanical power, simple programming, AI training, speed, ergonomic design and an integrated camera, it performs all picking activities.

In the incoming goods area, robots sort items from trolleys and place them directly into AutoStore warehouses. In outgoing goods, the robots remove the required items from the containers and place them in transport boxes for shipping.

Piece/Item Pick-by-Robot

Pick-by-Robot is an intelligent, AI-supported picking solution that automates the entire picking process. This solution is particularly suitable for picking stations with high throughput and a large variety of items, perfect for 24/7 operation. A flexible, fast and precise robot arm takes over the picking activities and adapts to a wide range of requirements thanks to various gripping tools. Thanks to communication via our HiLIS warehouse management system, the system can be easily integrated into existing intralogistics processes. Pick-by-Robot can be implemented independently or in combination with other storage and picking systems such as AutoStore® or AGVs.

Bin-in-Bin and Bin-out-Bin

SLC Picking

HÖRMANN Intralogistics is setting new standards in automation with its Bin-in-Bin and Bin-out-Bin SLC Picking solution. For the first time, complete SLCs can be stored and retrieved directly in AutoStore containers. The entire process is precisely controlled through the use of advanced image processing technology. For fully automated picking, the bin-in-bin and bin-out-bin picking solution can be combined with an AGV for goods transportation. The entire system is flexibly adaptable and can be seamlessly integrated into existing processes.

Videos

Item / piece picking

SLC / bin-in-bin picking

Contact us now

Would you like to make your automated warehouse even more efficient and are thinking about retrofitting it with cobots? We can provide you with manufacturer-independent advice on the solutions currently available.