From picking to truck loading

Highly automated material flow systems

More sensor technology, AI, interfaces, robotics and smart software make it possible: impressive warehouses with an ever-increasing degree of automation. Which technologies can already be implemented to move all classes of goods efficiently and error-free?

As a general contractor with heart and mind, we closely follow the trends, needs and challenges of our customers. Through real projects and inquiries, we get a feel for currently feasible and in-demand technologies for smooth material flow systems. The step into automation is still a big risk, and one that we fully support.

The coexistence and synergy of manual and automated warehouse areas, as well as retrofitting with robotics and sophisticated sensors to achieve a particularly high level of automation, are emerging as major trends. In this way, day-to-day business is not interrupted, but at the same time the shortage of skilled workers, susceptibility to errors and increasing picking speeds are countered. In addition, intralogistics processes for small to very large and bulky goods can be automated.

Are you facing similar challenges with your business? Take a look here to see what solutions major companies from trade and industry have found.

The advantages of highly automated material flow systems:

- Almost fully automated storage systems ensure maximum availability, better use of space, higher labour productivity and inventory accuracy, lower operating costs and the precise sequencing of goods for dispatch.

- Diversity of goods classes: from the smallest parts such as screws, seals etc. to bulky goods such as wood cuttings. from the smallest parts such as screws, seals, etc. to bulky goods such as wood cutting packages or machine motors, almost anything can be handled fully automatically thanks to smart technology and software

- Efficient and asynchronous supply of various internal and external customers

- Customization: Fulfillment of any end customer requirements without errors and failures

- Saving on hard-to-reach specialist personnel

- Increase in Throughput and storage capacity with scalability during operation

- Integration of areas that are still operated manually into the overall automated material flow system

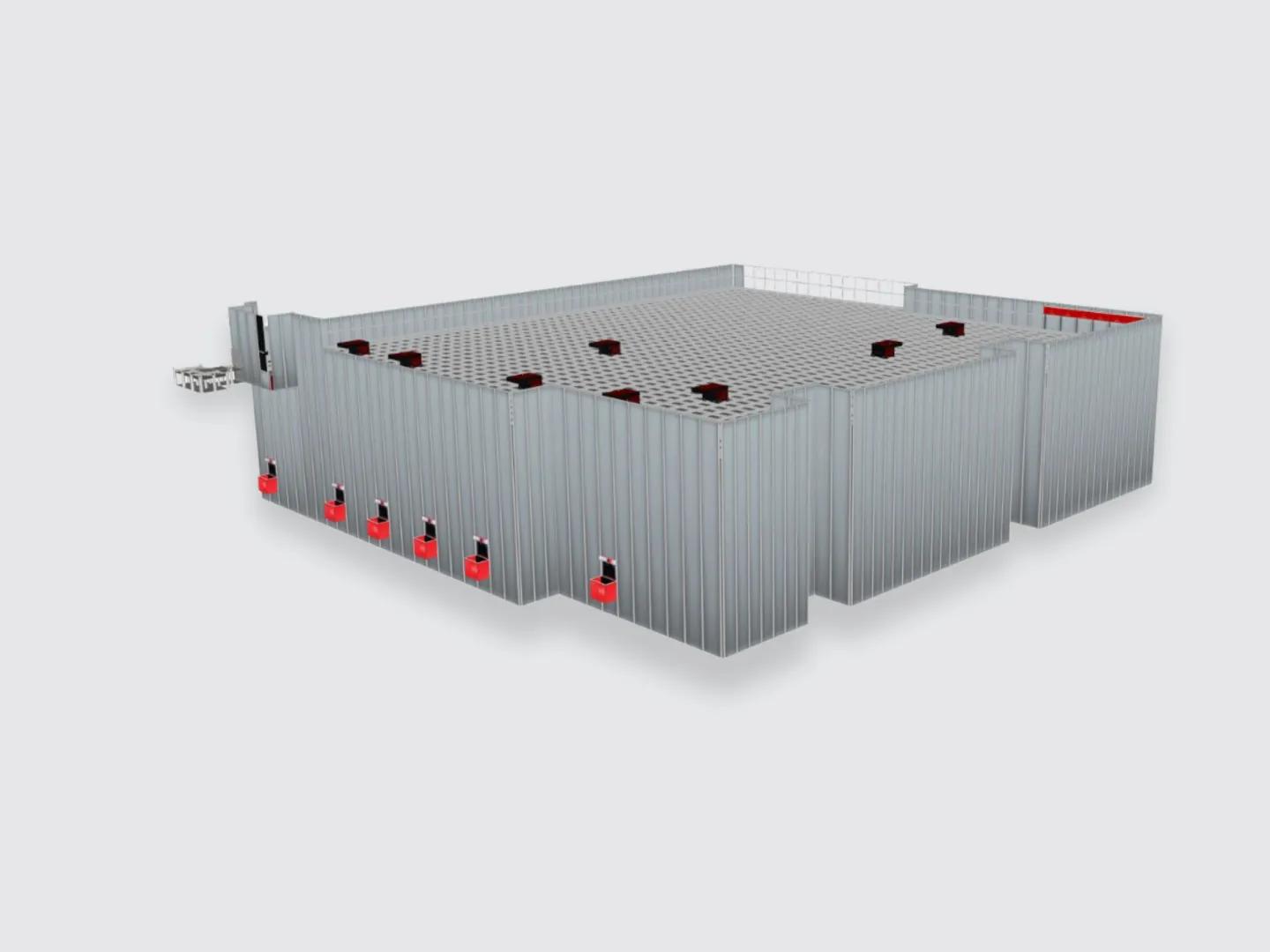

AutoStore system with innovative robot cell for Siemens

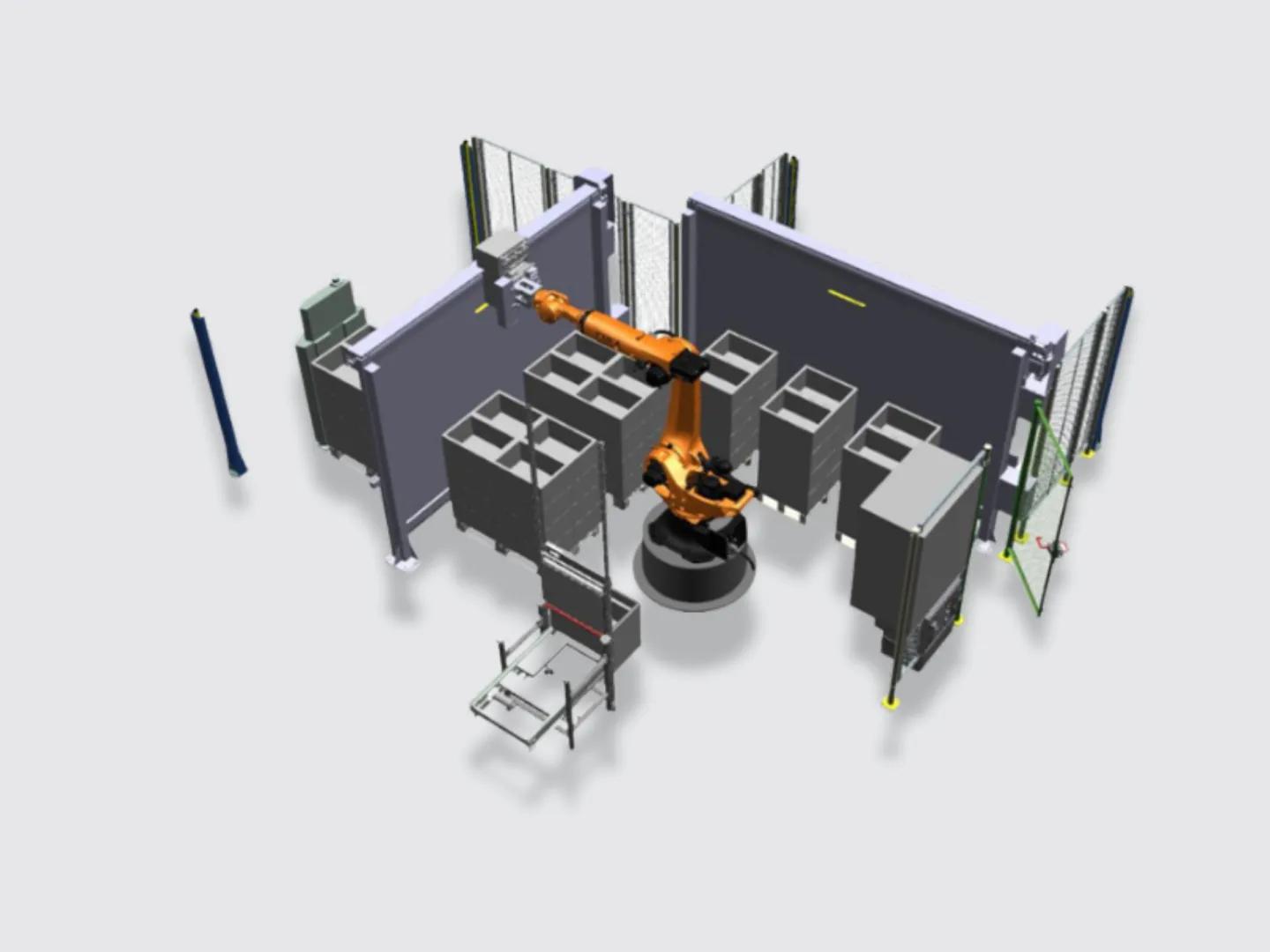

We are implementing an AutoStore system with an integrated robot cell for Siemens AG in Rastatt. This combination enables fully automated goods receipt of small load carriers into an AutoStore grid for the first time. The project sets new standards in the automation of intralogistics processes and offers a well thought-out concept for high speed.

A specially developed robot system with "bin-in-bin, bin-out-bin" technology is used to fully automate the incoming goods process. A Kuka robot, equipped with a special gripper and integrated vision technology, takes over the storage and retrieval into and out of the AutoStore Conveyer Port.

Facts

| AutoStore system | Robot cell |

|---|---|

|

|

Liebensteiner Kartonagen: New construction & retrofit of corrugated board high-bay warehouse + retrofitting of pallet AGV system

For our long-standing customer Liebensteiner Kartonagen in Plößberg, an impressive production and storage facility for corrugated cardboard was gradually built. With three retrofit and new construction phases between 2012 and 2025, capacity and the degree of automation were continuously increased.

All-in: Fully automated shipping and production supply with 13-aisle high-bay warehouse and driverless transport vehicles for pallets

Facts

| Pallet warehouse | FTF area |

|---|---|

|

|

Automated small parts and pallet warehouse for KraussMaffei

HÖRMANN Intralogistics has implemented a comprehensive intralogistics solution for the new KraussMaffei Technologies plant in Parsdorf. The order included an automated small parts warehouse (AKL) and an automated pallet warehouse (APL) with a conveyor system connection, combined picking stations, tower storage for sequencing and the complete automation technology. The warehouse is managed via SAP/EWM.

The high-performance system optimizes incoming and outgoing goods and supports KraussMaffei with the growing demand. Despite challenging framework conditions, the project was successfully implemented and put into operation.

Facts

| AKL | APL |

|---|---|

|

|

Automatic high-bay warehouse, packaging line and loading hall for timber

HÖRMANN Intralogistics has implemented a pioneering intralogistics solution for the Mayr-Melnhof Holz Group in Leoben, based on the functional specifications of logistics planner Xvise from Lauterbach (Austria), which makes the long-established company a trailblazer for the wood processing industry. The combination of an automated, three-aisle high-bay warehouse with innovative conveyor technology, a complex packaging line and, for the first time, a semi-automatic truck loading hall sets new standards in timber logistics.

Project objectives and challenges:

- Efficient and asynchronous supply of three areas: External customers, MMH Geishorn site, cross laminated timber production

- Lubricating oil-free transport of the living natural product with board length differences

- Packages with and without scantlings as well as foiling on the same packaging line

- Largely automated, capacity-optimized truck loading

Facts

| High-bay warehouse | Packing line & truck loading hall |

|---|---|

|

|

Reference film: Intralogistics for the timber industry - at Mayr Melnhof Holz in Leoben | EN

Analyze material flow & get an expansion recommendation now!

Would you like to take your automated or semi-automated warehouse to the next level? We look at your current and target situation and suggest manufacturer-independent expansions or new builds. Please feel free to contact us without obligation.