Robotics

AutoStore® for compact, highly dynamic small parts storage and picking

AutoStore® is an innovative, cutting-edge system for automated small parts storage and picking in plastic bins. This compact system optimises volume utilisation, dynamics, energy efficiency, expandability, material usage, and connections to picking stations.

As an official distributor, HÖRMANN Intralogistics offers AutoStore® with the HiLIS AS WMS tailored to it, along with all-round customer service as a general contractor.

The advantages at a glance

- Floor space reduced by up to 75%

- The Red& Black-Line robots tirelessly pick up bins, re-sorting and delivering them to the ports directly couple for receiving and picking goods.

- AutoStore® is a completely modular system, with throughput capacity determined by the number of robots and workstations.

- AutoStore® can be installed as a stand-alone solution or integrated into an overall logistics concept.

What it AutoStore®?

AutoStore® is an automated storage system that harnesses the power of warehouse robots for around-the-clock order fulfilment in a cubic layout so dense it can quadruple storage capacity and unlock the true potential of your warehouse space.

Our Partner

HÖRMANN Intralogistics is a long-standing distributor and system integrator of the world-renowned AutoStore® solution. In close partnership with the manufacturer, as general contractor we offer the CubeStorage system along with a specifically tailored HiLIS AS WMS, which is also capable of mapping manual storage areas and managing additional processes.

With the support of our trusted partners, we’ve already successfully implemented more than 50 groundbreaking automation solutions.

The solution in detail

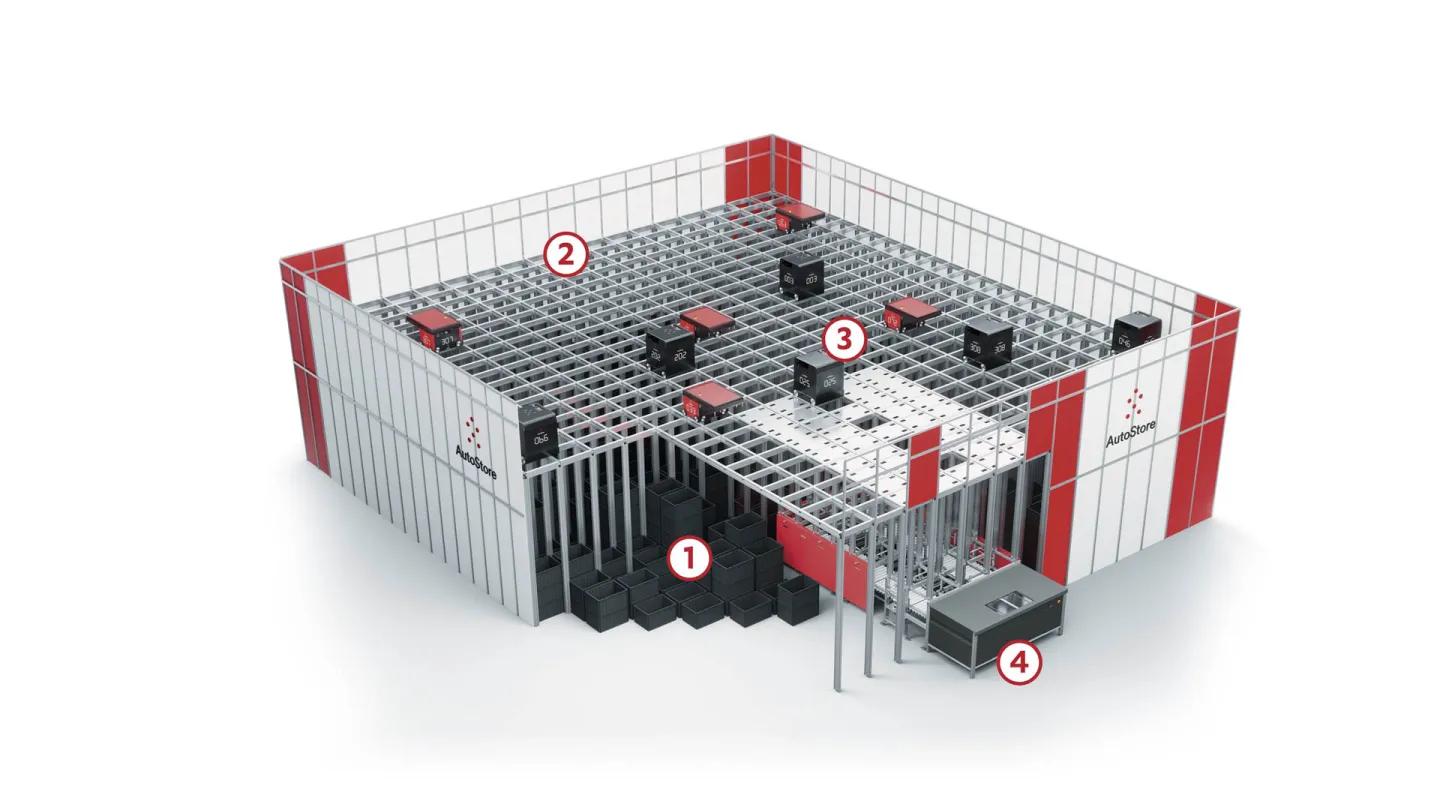

Bins

These sturdy and stackable bins, available in three different heights, can carry a maximum weight of 35 kg, and are also available in anti-static ESD version.

Grid

The self-supporting aluminum structure holds the bin stacks and guides the robots on the rails. Being modular, the grid can be arranged in any layout.

Red & Black Line line robots

With two pairs of wheels arranged crosswise, the AutoStore® robots can move in two directions, enabling them to reach any position in the grid to pick up, transport and set down bins.

Ports (picking modules)

Ports can be installed on all sides of the AutoStore® system and supplied by the robots without interruption. The ports are used for efficient picking and filling of the bins.

Controller

This module is the AutoStore® command, traffic control and database management centre.

AutoStore® in your warehouse - how it works:

- Bins

- Grid

- Robot

- Ports (picking modules)

-

Controller

- HiLIS AS Warehouse Management System

Download Whitepaper

E-Commerce & Logistics Systems of the Future

- Mega-trends & social discourses

- Fulfilment strategies at a glance

- Micro-fulfilment centres in detail perspective

- Practical examples from food to electronics

(in german)

Download nowPorts (picking modules)

Ports can be installed on all sides of the AutoStore® system and supplied by the robots without interruption. The ports are used for efficiently picking and filling the bins.

Depending on the type, the picking performance is between 160 and 650 items per hour.

- Maximum bin throughput - 400 bins/h on ground level, 500 bins/h on intermediate levels

CarouselPort - three-armed port

The CarouselPort works with three rotating arms, each one equipped with a bin pickup.

Maximum bin throughput:

- 350 bins/h average

- 500 bins/h theoretical maximum

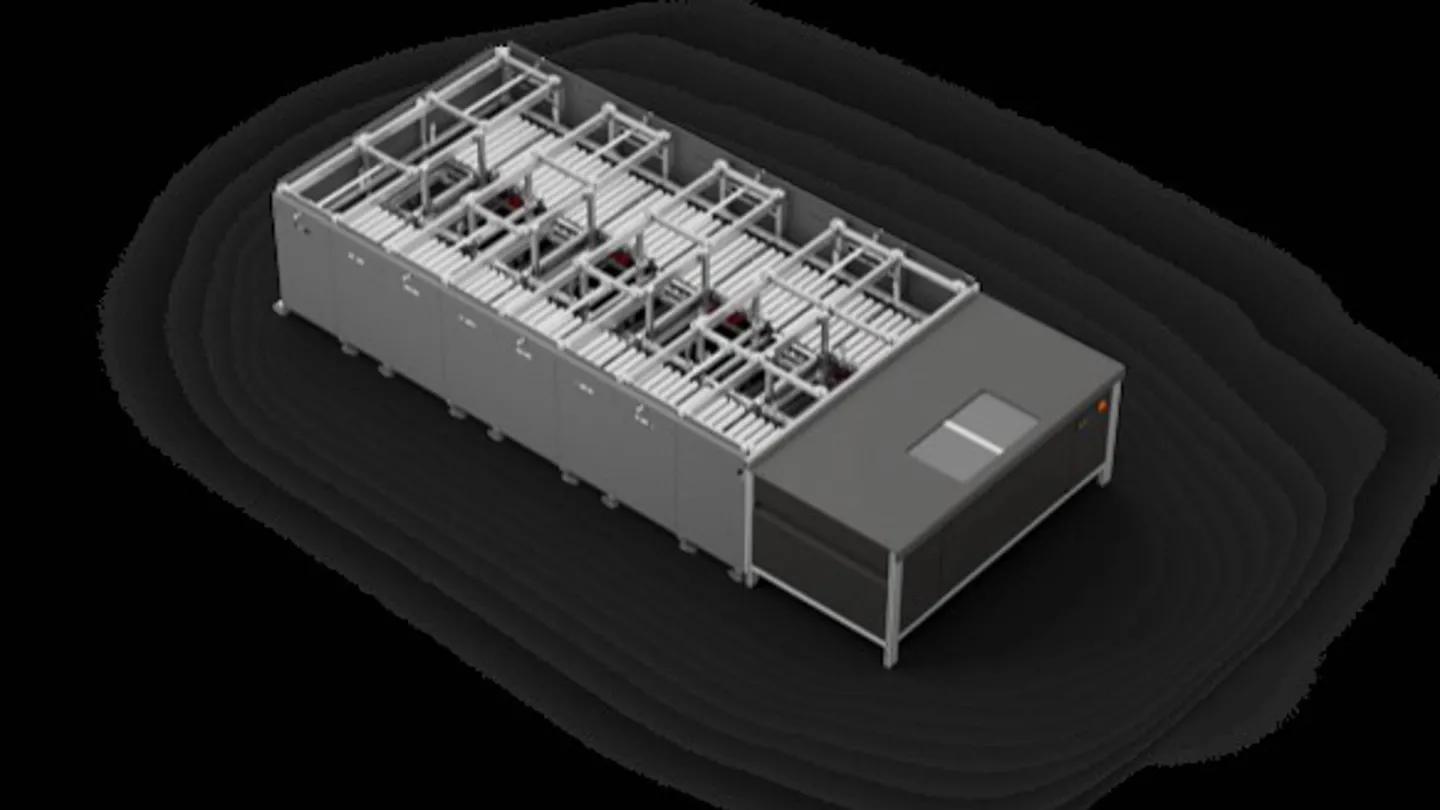

ConveyorPort - straightforward workstation

The ConveyorPort uses a conveyor belt to bring bins to the operator. While one bin is presented to the operator, the second bin is held ready above the port by a robot.

Maximum bin throughput:

- 240 bins/h on an intermediate level

- 180 bins/h on the floor level

RelayPort - fastest possible bin availability

This modular workstation consists of the Touch picking module and buffer modules called tabs. Each picking station can have 3 to 6 tabs. The robots are able to reach the selected positions from any direction. With the TabSystem, robots fetch a bin back into the grid as soon as a bin is released.

Maximum bin throughput:

- 650 Bins/h

SwingPort - vertical connection

The SwingPort uses a rotating arm to deliver bins to the operator. While one bin is presented to the operator, the second bin is in waiting position at the opposite end of the arm.

Maximum bin throughput:

- 160 Bins/h mit 8 m BinLift

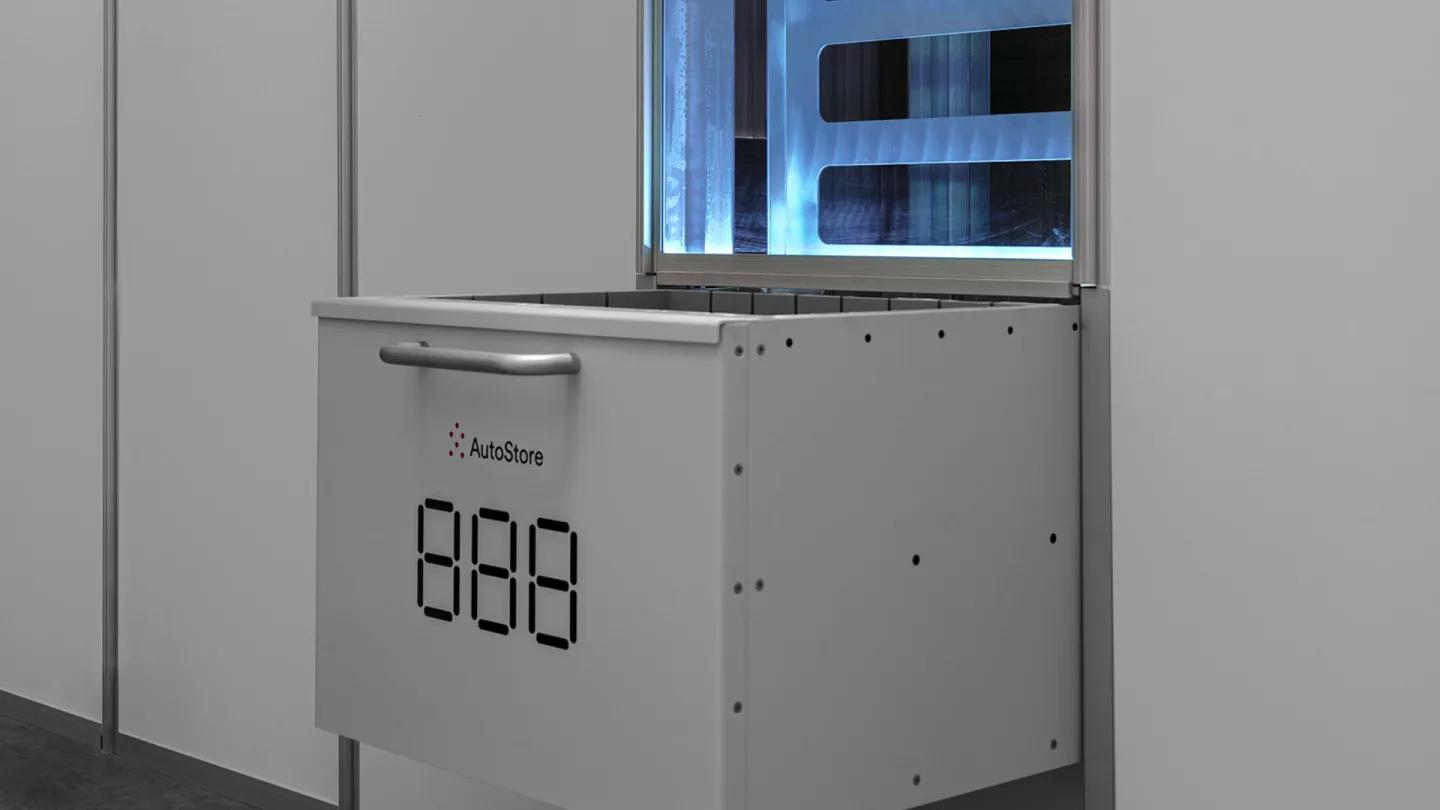

PickupPort - Automated end customer pickup station

PickUpPort is a public access point that enables contactless in-store pickup of online orders directly from AutoStore. With PickUpPort, retailers can easily and cost-effectively implement a BOPIS (Buy Online Pickup In-Store) omni-channel retail strategy, attract and retain customers, and ultimately increase sales.

The PickUpPort is available in narrow or wide versions and takes up no additional space next to the system when locked.

Contact us now

AutoStore® is custom configured according to your requirements, determined on the basis of simulations. Your quantity structures, item/order structure and performance requirements determine the size, number of robots and number of picking modules.

AutoStore® is suitable for both low performance and large bin capacity requirements, as well as highly dynamic requirements demanding several thousand storage and retrieval operations per hour.