Intralogistics

Automated pallet warehouses - individual and highly available

Where goods and merchandise need to be stored in a limited space, we recommend a custom-made high-bay storage system with fully automated stock storage and removal, from goods receipt to dispatch readiness. For pallets, boxes, rolls, stacks, big trays or cartons in different formats and with different weights, we build SRM-based high-bay warehouses as in-house or silo systems, in addition to high storage density and high throughput pallet shuttle systems.

The advantages at a glance

- High-level item variety

- Space saving

- Storage up to four deep

- Effective stacker crane utilisation through double, triple and quadruple formation

- Storage and transport or a wide range of LU sizes

- Storage and transport with or without sub-pallet

- Connected custom-made conveyor technology

All you need to know about automatic high bay warehouses

Brochure- Intralogistics Solutions

Your contact - Michael Hoffmann

What is an automatic high-bay warehouse?

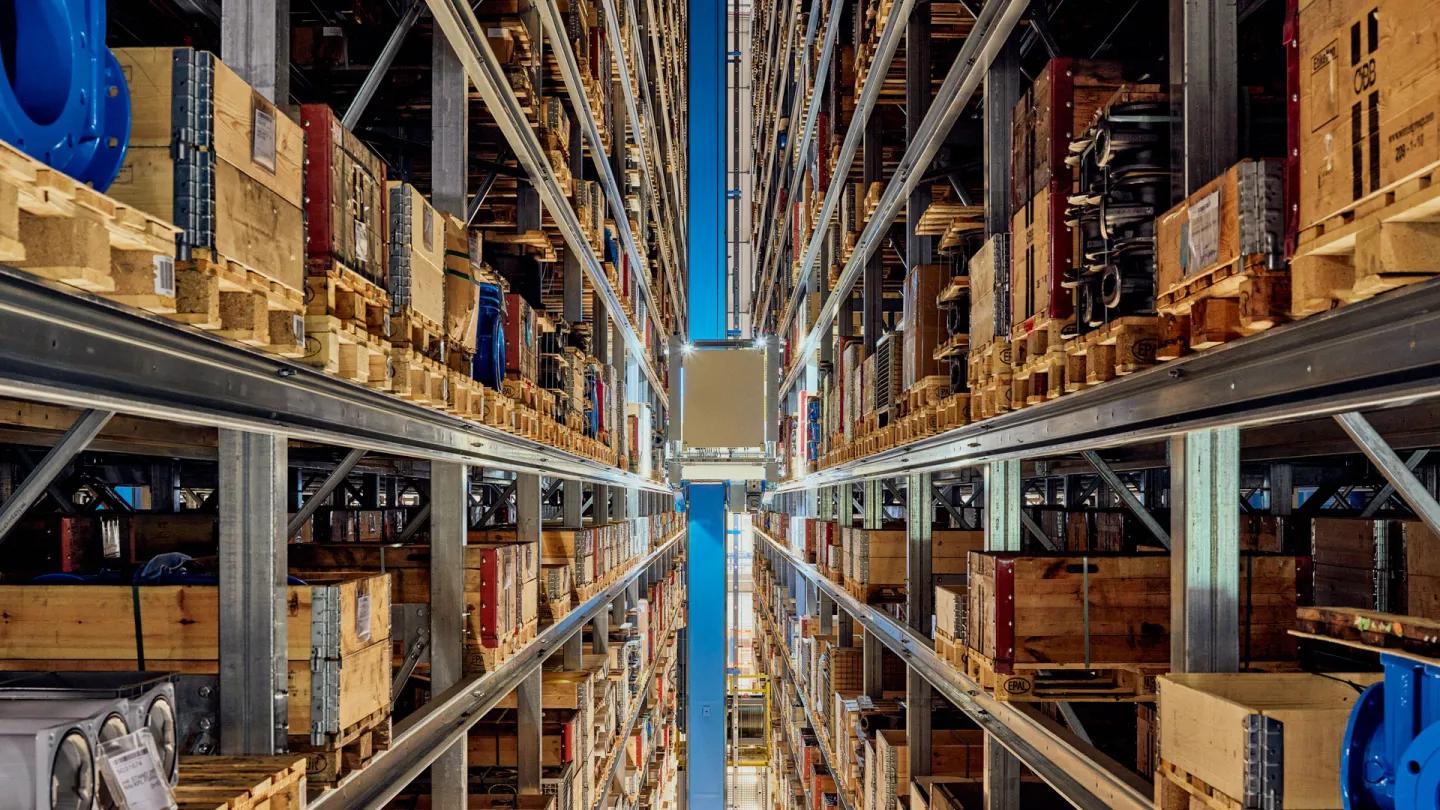

An automatic high-bay warehouse is a warehouse with a height of over 12 meters, consisting of a number of aisles with steel rack structures. Pallets or load units without pallets can be stored in the compartments of the racks. Each aisle is served by a stacker crane, which automatically stores and retrieves the various items.

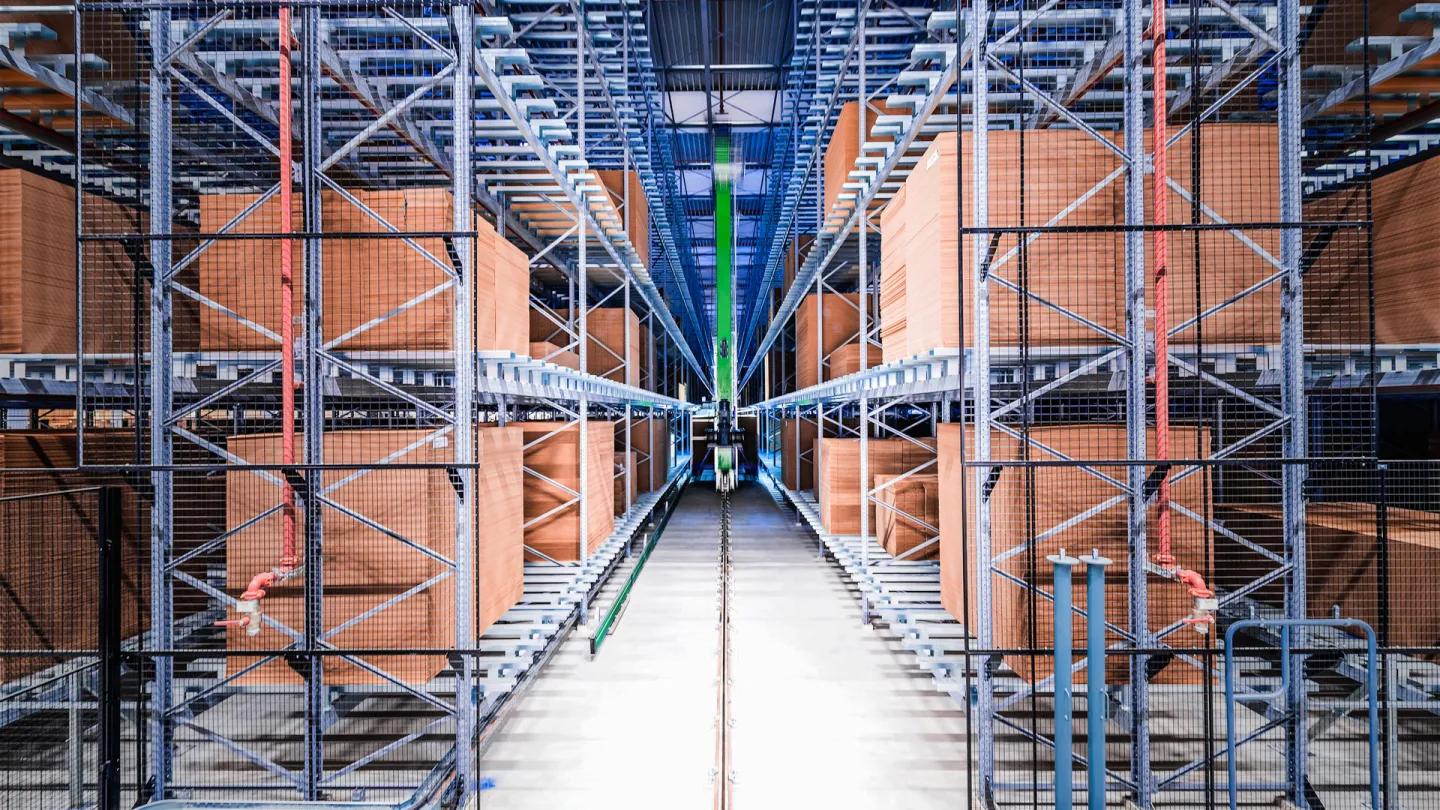

FRIPA Paper Factory Albert Friedrich KG, Miltenberg, Germany

How it works

We build high-capacity, high-bay warehouses for a wide range of items, with single-deep or two-deep storage.

To meet your particular requirements, we also implement multi-deep, channel-storage systems, as a particularly space-saving and efficient solution for warehouses with larger stocks per item, with the highest level automation.

Our special telescopic fork technology can achieve up to four- deep pallet storage, and with channel storage technology can go even deeper. Modern channel vehicles place every pallet (measured prior to storage) at the channel position specified by the WMS with millimetric precision, for optimal volume utilisation.

We manage to achieve the highest flexibility and performance for storing different sized formats using a special technology that permits load unit storage and retrieval with up to nine sub-pallets, or single, double, triples and quadruples, with one stacker crane cycle.

Our services at a glance

Shelving systems

- Silo constructions

- Recessed shelving constructions

- Single-space systems

- Multi-user space systems

Storage type

- Single-deep

- Multi-deep

Loading aids

- Pallets

- Palletless stacks

- Special customer load carriers

Stacker crane

- 1-mast configuration

- 2-mast configuration

- 4-mast configuration

- Telescopic fork technology

- Channel vehicle

Techniques

- Travel curve control

- Regenerative energy

- Intermediate circuit technology for immediate energy reuse

- Laser or camera system fine positioning

- Compartment fine positioning self-teaching

- Variable acceleration according to device load

- Algorithmic path optimisation

Periphery

- Roof and wall cladding

- Smoke and heat exhaust

- Fire alarm system

- Sprinkler system

- Inerting

- Fire doors

- Locks

- Lighting

- Heating

- Air conditioning

Contact us now

Automatic high-bay warehouses tailor-made and with state-of-the-art technology from HÖRMANN Intralogistics. We bring all of our expertise to bear on every project and provide custom-made all-round solutions to ensure the success of your business.