AutoStore incoming orders

Automation for builders' merchants: J.N. Kreiller KG relies on AutoStore

J.N. Kreiller KG from Traunstein, a leading retailer for the main and ancillary building trades, is driving forward the digitalization of its own logistics. HÖRMANN Intralogistics was commissioned to implement an AutoStore system that will significantly increase storage capacity, throughput and process flexibility.

Flexible system for versatile requirements

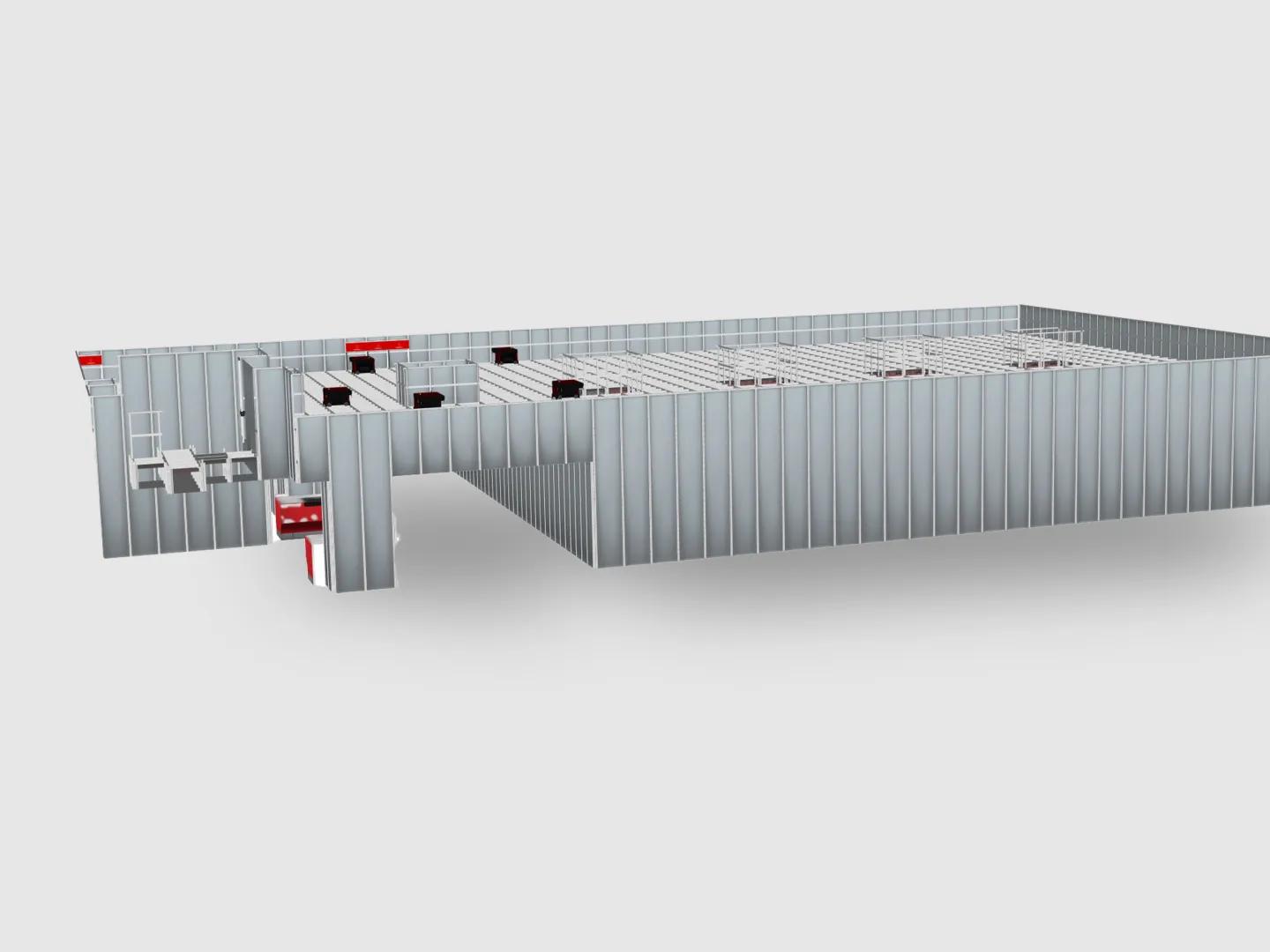

The new AutoStore grid will comprise 11,840 containers with a height of 330 mm in the first expansion stage. Eight robots from the "Red Line" series take care of automated storage and retrieval, supported by just as many loading stations. The four carousel ports are arranged in a tunnel and designed so that both incoming goods and order picking can be carried out at each workstation. This flexible design enables resources to be used as required. The system will be built in two phases, with a second construction phase to expand the system to 26,000 containers.

HÖRMANN's in-house warehouse management software HiLIS WMS will be used to control the system. The system will achieve a storage capacity of 110 containers per hour. Retrieval will take place at a speed of 150 containers per hour. A large proportion of the order items are counter orders, which can be processed within a few minutes.

A step into the future

Marco Traubinger, Managing Director of J.N. Kreiller KG, is looking forward to the changes that the new system will bring: "AutoStore will significantly improve our processes. It will be particularly interesting to see how our customers react to the increased efficiency and shorter delivery times."

With this investment, Kreiller is positioning itself for the future and strengthening its competitiveness in the builders' merchant sector. The implementation work is underway, with commissioning scheduled for the end of July 2025.