Robotics retrofit

HÖRMANN Intralogistics drives paradigm shift in warehouse automation

With two new projects at existing customers Esders and W-Music Distribution, HÖRMANN Intralogistics is pleased to announce a "quantum leap" in automated warehouse systems. The combination of AutoStore, driverless transport vehicles and AI-controlled robots further increases the degree of automation - beyond classic goods-to-person concepts to the complete autonomy of repetitive processes such as container handling and order picking.

Esders: AutoStore meets automatic guided vehicles

Esders GmbH is expanding its existing AutoStore system in Haselünne with an intelligent transport solution that moves containers fully automatically between the warehouse and order picking. Hörmann Intralogistics had already implemented an AutoStore grid with 3,000 bins and six robots for the storage and picking of measuring and equipment technology at the site in 2018. The system has since been expanded to 6,000 bins and ten robots.

Nine SAFELOG XS 1 vehicles take over the transfer of the AutoStore containers to the conveyor system, navigate independently through the warehouse and charge themselves autonomously at induction charging stations.

Bernhard Esders, Managing Director of Esders GmbH, sees this step as a pioneering development: "We are not only automating individual processes, but also networking our entire value chain in a way that was hardly conceivable just a few years ago. The integration of AutoStore with driverless transport systems increases our efficiency and flexibility enormously."

This project is a first for HÖRMANN Intralogistics: for the first time, AutoStore is being combined with an AGV fleet to control the material flow efficiently.

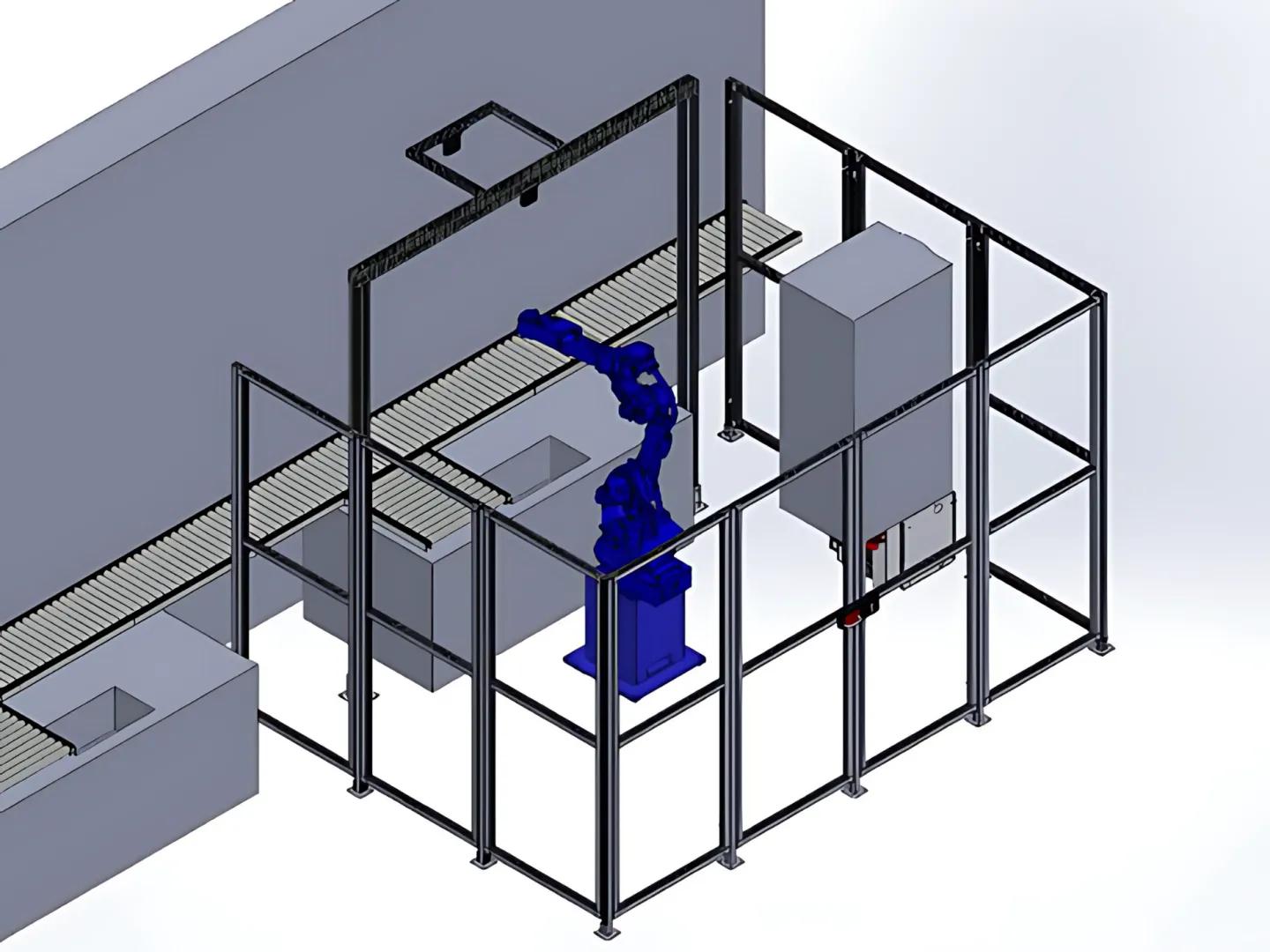

W-Music Distribution: robots take over picking

At musical instrument retailer W-Music Distribution in Marktneukirchen, automation is going one step further. Two picking robots with AI-supported image recognition from Hörmann partner Sereact are replacing the manual storage and retrieval of items in AutoStore bins. This was implemented in 2022 with 16,600 bins and five robots from Hörmann Intralogistics.

In the incoming goods area, the first robot takes over the sorting of items from trolleys and places them directly into the AutoStore. By using zero-shot learning and the "PickGPT" from Sereact, picking robots can now recognize and pick new objects without prior programming or data input. In the outgoing goods area, a second robot removes the required items from the bins and places them in transport boxes for shipping. The existing conveyor technology is adapted accordingly and integrated into the HiLIS warehouse management system.

Nicolas Wilfer, CEO of W-Music Distribution, sees this step as a fundamental change: "With this technology, we are moving towards fully automated logistics. We are reducing monotonous manual operations, speeding up processes and creating the basis for a scalable, future-proof warehouse structure."

These two projects put HÖRMANN Intralogistics at the cutting edge of current developments in the fast-moving and complex world of robotics and automation. The combination of AutoStore, intelligent transport robots and AI-controlled picking in customers' live systems is a turning point in intralogistics - from semi-automated processes to fully networked, autonomous warehouse control.

"As a general contractor, we remain close to our customers' developments following the handover of the first project. They increasingly want more advanced automation steps that are easy to integrate, work reliably and have an economic ROI. Following extensive development phases for the two exciting projects, we will be able to guarantee these services across the board for existing customers and new projects in the future," summarizes Tom Walther, Head of Robotics at Hörmann Intralogistics.

The realization of both expansions is planned for summer 2025.