Incoming orders

HÖRMANN Intralogistics supplies state-of-the-art AutoStore system to HAIX

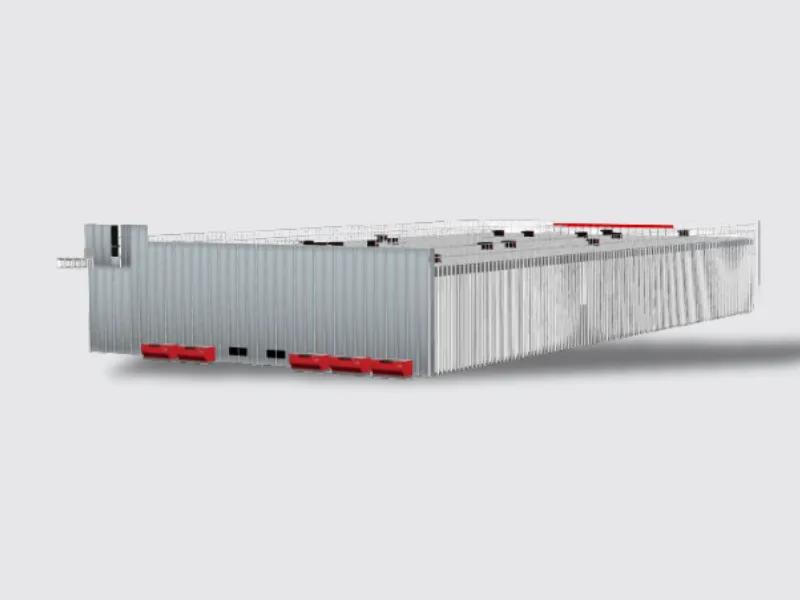

Munich, December 2024 - HÖRMANN Intralogistics has been awarded the contract as general contractor for the automation of intralogistics at Haix, an internationally renowned manufacturer of functional and safety footwear. As part of this project, HÖRMANN Intralogistics will integrate a state-of-the-art AutoStore system into the HAIX logistics site.

Increasing efficiency and optimizing space

The new AutoStore system at HAIX is designed for the storage and quick access of up to 50.000 containers at a height of 425 mm over 14 levels and uses an area of 51 x 26 m. With 18 robots and 5 Carousel workstation modules, the system is designed to significantly increase the efficiency of storage and retrieval processes. It can handle 110 storage and 450 retrieval operations per hour.

A milestone for logistics at HAIX

The use of the AutoStore system marks an important milestone in the optimization of logistics processes at HAIX. "With the new AutoStore system, we are relying on state-of-the-art technology to make our logistics more efficient and powerful," says Alexander Krüger, Head of Logistics Center at HAIX. "This investment enables us to further improve our customer service and at the same time be prepared for future requirements."

Extensive competition

The intralogistics conversion was preceded by an extensive tendering phase. Hörmann Intralogistics was able to assert itself through high commitment, speed and planning expertise and convinced the HAIX team. "We are looking forward to working with Hörmann Intralogistics and are confident that we have found a reliable and competent partner," continues Alexander Krüger.

Commissioning

The installation of the AutoStore system at HAIX is expected to be completed in the fourth quarter of 2025. The test and introduction phase will then begin so that the system can go into operation as planned at the beginning of 2026.