New development of a work-in-progress and finished goods warehouse

Hörmann Intralogistics takes on major order for Wellpappe Alzenau

Munich, January 2025 - Hörmann Intralogistics has secured a major contract as a general contractor: Hörmann is developing and implementing a modern high-bay warehouse concept including custom-fit conveyor technology based on the specifications of the logistics planner iBH Schepper for the new plant of Wellpappe Alzenau GmbH & Co. KG in Alzenau. This means that the plant's intralogistics are optimally adapted to the production and further processing of corrugated board.

Wellpappe Alzenau is part of the Palm Group, based in Aalen, Baden-Württemberg, one of the leading manufacturers in the paper and packaging industry.

Efficiency meets innovation: The logistics concept in detail

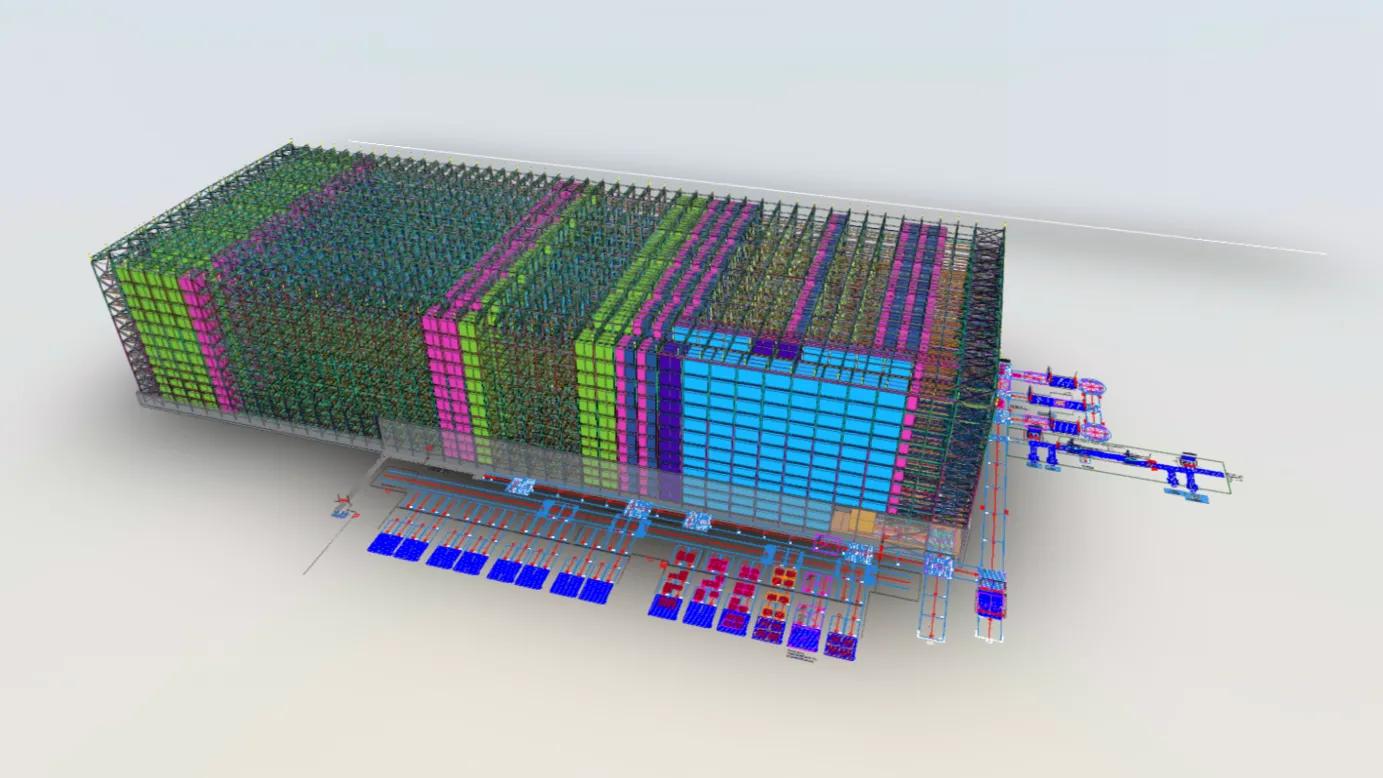

The project comprises two high-bay warehouses, both of which are individually tailored to the requirements of Wellpappe Alzenau:

Work-in-progress warehouse (WIP):

- On an area of approx. 70 x 30 meters and a height of 34 meters, a 3-aisle, 2-fold deep high-bay warehouse in silo construction is being built. Three two-mast storage and retrieval machines with telescopic forks ensure an efficient material flow.

- Format stacks are stored without sub-pallets and without strapping. The conveyor system takes over the corrugated cardboard stacks directly from the corrugator, connects the WIP with a pallet circuit and transports the stacks from the WIP to the distribution trolleys in the processing hall.

Finished goods warehouse (FGWH):

- A 5-aisle, multi-deep high-bay warehouse is built for the finished corrugated board packaging. Five two-mast storage and retrieval machines with sewer vehicles ensure sufficient storage and retrieval performance.

- The conveyor system connects to the end of the packaging line and connects the finished goods warehouse and shipping with a pallet circuit. The dispatch pick-up points are floor-level for the use of electric pallet trucks and counterbalance forklifts.

High-performance modular belt conveyors are used in both storage areas. The scope of supply also comprises of shelf steel construction, a sprinkler system, fire protection doors and continuous LED lighting of the front zones and alleys. The warehouse management software HiLIS WMS from Hörmann is used for digital control and optimization, which monitors the entire material flow and ensures smooth integration into the production processes.

Statements on the cooperation

Jens Schuhmacher, Managing Director of Wellpappe Alzenau, is pleased: "With Hörmann Intralogistics, we have found an experienced partner who offered a complete solution from a single source. Their concept convinced us with technical excellence and focus on efficiency and flexibility. The new logistics system will play a crucial role in taking operations at our plant to the next level."

"For us, this project is a great opportunity to prove our know-how in the field of intralogistics and to support Wellpappe Alzenau in optimizing its processes," adds Mark Schulz, Sales Project Manager at Hörmann Intralogistics. "Our combination of robust warehouse technology and intelligent software is specially designed to meet the high demands of production and logistics processes."

Construction and commissioning are planned for mid-2025/2026 with SOP in spring 2026.

About the Palm Group and Wellpappe Alzenau

The Palm Group is one of the leading manufacturers of paper and corrugated board in Europe. With a total of 5 paper mills and 29 corrugated board plants, the company produces paper from 100% recycled paper as well as sustainable packaging solutions for a wide range of industries. The new plant in Alzenau relies on state-of-the-art technologies to ensure highly efficient processes and particularly sustainable production. In addition to the production of high-quality corrugated board packaging, a special focus is placed on resource-saving processes – an approach that Hörmann Intralogistics also supports with its innovative solutions.

About HÖRMANN Intralogistics:

HÖRMANN Intralogistics is a leading provider of innovative and tailor-made logistics solutions. With a comprehensive portfolio of services and technologies, the company supports its customers worldwide in optimizing their logistics processes and increasing their efficiency.