Innovative intralogistics solution with pallet shuttle, miniload and conveyor technology for Windhager

World's first combined chilled and ambient AutoStore® system for online retailer flaschenpost SE.

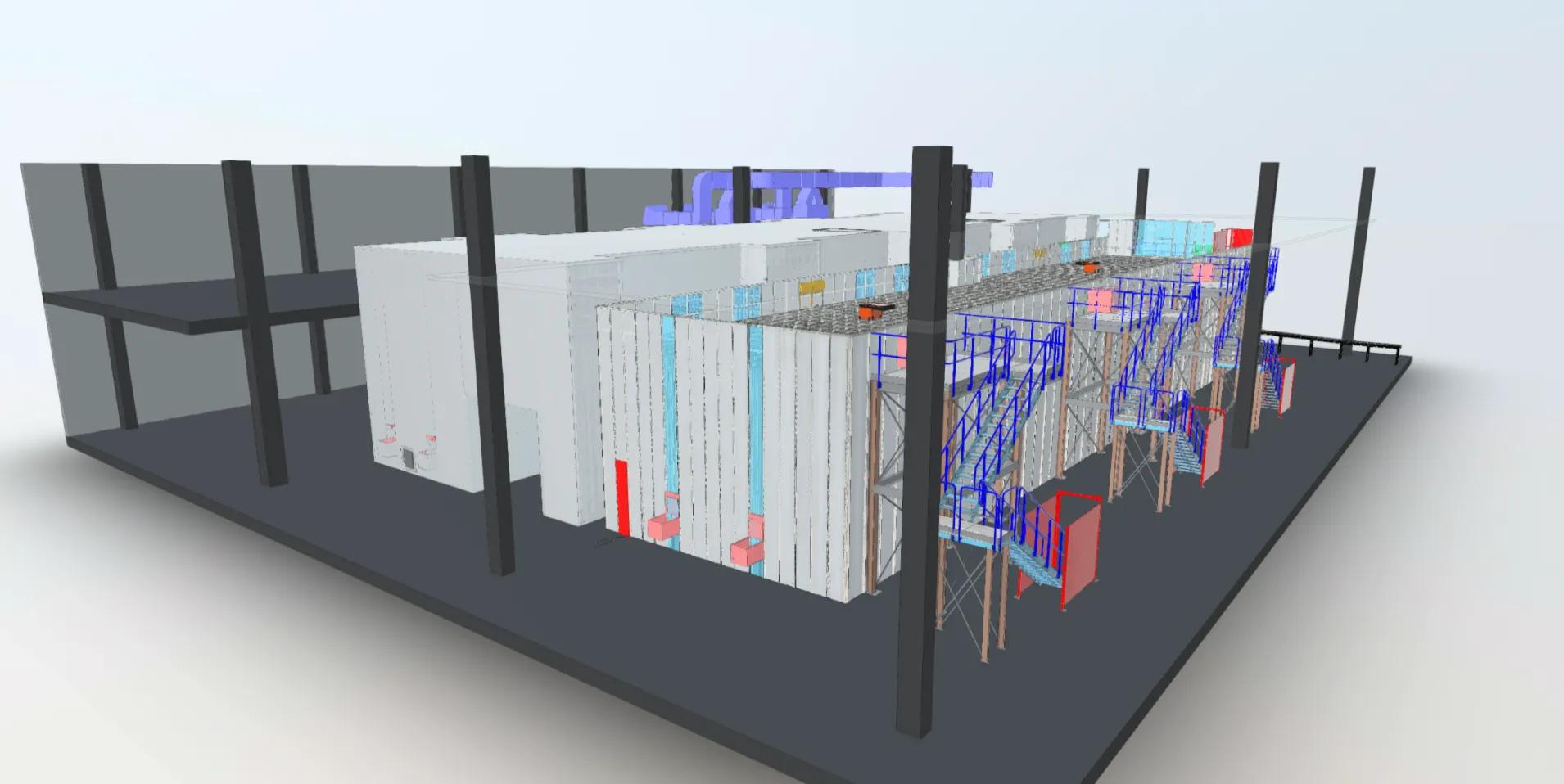

The online supermarket flaschenpost went online with its instant delivery service in 2016 and today delivers food, beverages and everyday products to more than 200 cities in Germany. Over 20,000 employees currently ensure that the promise of "delivery within 120 minutes" is fulfilled from over 30 warehouse locations. At the site in Langenfeld (Rhineland) HÖRMANN Intralogistics builds for the first time in an existing property a micro-fulfillment solution with two combined AutoStore® systems, the connecting conveyor technology and the necessary cooling system.

Refrigerated and non-refrigerated goods with up to 9,500 container tenders per day.

For the innovative design of the AutoStore® system, the different temperature zones "Ambient" and "Chilled" were combined in the planning of HÖRMANN Intralogistics so that it is possible to pick dry and chilled goods from both systems for one order.

André Damkowski, Senior Logistics Engineer at flaschenpost, looks forward with excitement to the implementation work currently underway: "The extensive expansion of the product range to include foodstuffs and growing demand required further development of our intralogistics processes through the use of automation technology. The cooperation with Hörmann Intralogistics in the design and detailed planning of the innovative and tailored to our needs solution ran very cooperative."

The required operating hours of 16 hours, 6 days a week, together with other customer requirements and the simulation results, led to the following system configuration: the AutoStore system "Chilled" for refrigerated goods comprises approximately 8,500 AutoStore containers, which are placed in stacks directly on the floor on 16 levels in the approximately 10 m x 40 m (L x W) grid system. 18 "Red-Line" robots move in two directions on the track system (grid) through their four pairs of wheels arranged at an angle, reaching every position on the grid. They tirelessly pick up totes, store, re-sort and operate the eight conveyor ports ready for storage and picking..

Also included in the scope of delivery is the complete enclosure of the chilled system as well as the cooling technology to operate the system at 2°C. A specially adapted cooling system ensures minimal leakage during operation and optimal energy efficiency.

Directly adjacent is the "Ambient" AutoStore® system for room temperature items in the flaschenpost warehouse. Approximately 10,000 bins are available on 16 levels in the 8 m x 40 m (L x W) grid system. 25 robots supply on the grid the eight carousel ports for storage and retrieval.

This advanced architecture for an automated eGrocery distribution center is the result of a trustful cooperation: "With a lot of courage to go new ways, we were able to win flaschenpost as a partner after an intensive project planning phase. This AutoStore system is unique in the world in terms of the arrangement and design of the various temperature levels," sums up Tom Walther, Business Development Manager at HÖRMANN Intralogistics.

The system is calculated in the current configuration for circa 1,000 container tenders per hour, but offers further growth possibilities of performance and storage space capacity. For the delivery and removal of the empty or order totes at the picking stations, approx. 100 m of connecting tote conveyor technology is installed. Up to 12,000 articles can thus be transferred per day to the flaschenpost delivery driver.

The combined AutoStore® system in Langenfeld is a pilot project for other company locations and is scheduled to go into operation in mid-2023. For HÖRMANN Intralogistics, this order is a milestone in the strategic growth segment Micro-Fulfillment Center.

www.hoermann-intralogistics.com, April 2023