News 2018

2018

Trade and various sectors

Chemicals & Pharmaceuticals

Automotive

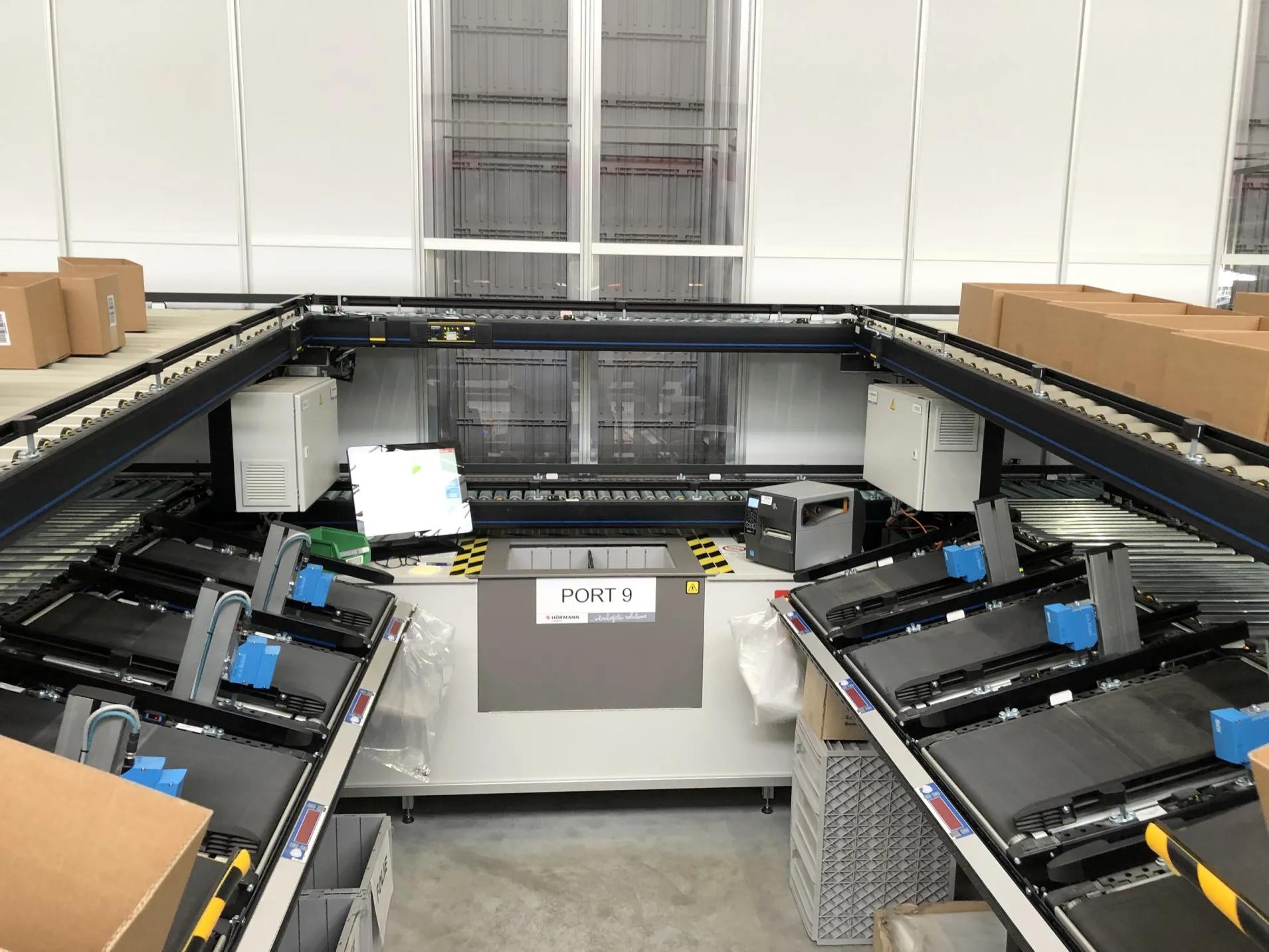

Order Picking Systems for Efficient Logistics

Logistics is one of the industries that respond to an ever-increasing digitalisation and automation: We painstakingly adapt our order picking systems to advancing warehouse technologies and your needs.

The systems are centred around the two principles of “goods to person” or “person to goods” and smoothly integrate in automated processes. Various tools such as pick-by-light or pick-by-voice provide you with innovative order picking technologies aimed at making your logistics processes more efficient.

Our total project portfolio is focused on adapting the order picking systems to each of our customers’ logistics processes.

What is an order picking system?

Generally speaking, order picking refers to compiling certain items of an assortment. Every company has its own set of items to be picked. The actual process of the order picking system of choice is based on order-specific, local and time requirements, and covers item withdrawal, transfer and dispatching.

Normally, order picking systems break down into material flow, information or organisation systems. One of the consequences is that order handling details are transferred in different ways, e.g. by radio, optically or acoustically.

Order picking principles

There are three basic principles of order picking, i.e. “person-to-goods”, “goods-to-person” and “pick-by-robot”.

A person-to-goods solution assumes that a person picks the requested items from the storage area to successively compile the order.

A goods-to-person solution assumes that items are automatically retrieved from a picking location containing bins or pallets. Once the items have been picked at the order picking workstation, the empty or partly empty bins or pallets are returned to the warehouse and stored there.

In the case of low-volume orders or items not suitable for automatic warehousing and conveying methods, you will normally apply the person-to-goods principle. It involves lower investments because all you need is a pallet store or free floor space.

However, goods-to-person solutions and automatic order picking are ideal because they are more efficient. They help you reducing transport times and require significantly fewer persons working in the warehouse.

The pick-by-robot principle assumes that all order picking processes are fully automatic. Instead of persons, robots complete all jobs involved in compiling items for one or more orders.

Key order picking methods and techniques

There are many different order picking systems adapted to the applicable requirements. It takes specific solutions, since every warehouse is different. This is where HÖRMANN Logistik comes in. We design custom-fit order picking solutions for your intralogistics needs. Key order picking technologies include:

- Pick-by-Light

- Put-to-Light

- Pick-to-Belt

- Pick-by-Voice

- Pick-by-Vision

- Mobile devices plus scanner (MDE, tablet PC, stacker terminal etc.)

The pick-by-light process is based on a light signal indicating the bin locations and the number of items to be picked. The order picker confirms that an item has been picked from the bin location.

Put-to-light is normally applied in a goods-to-person order picking concept. This approach is designed to handle the picking of several orders at the same time. A light signal indicates the order associated with the items just picked.

Pick-to-belt is an order picking system assuming that article items are picked from a bin location and placed directly on a conveyor belt – often feeding a downstream sortation system.

Voice-based order picking systems such as pick-by-voice use an automatic computer voice to acoustically send the order details to the picker’s headset. Vice versa, the picker uses the same voice control system to confirm the orders.

Pick-by-vision is an innovative type of order picking system. Smart glasses display the required details to the picker’s own view. The signals guide the picker to the next picking point.

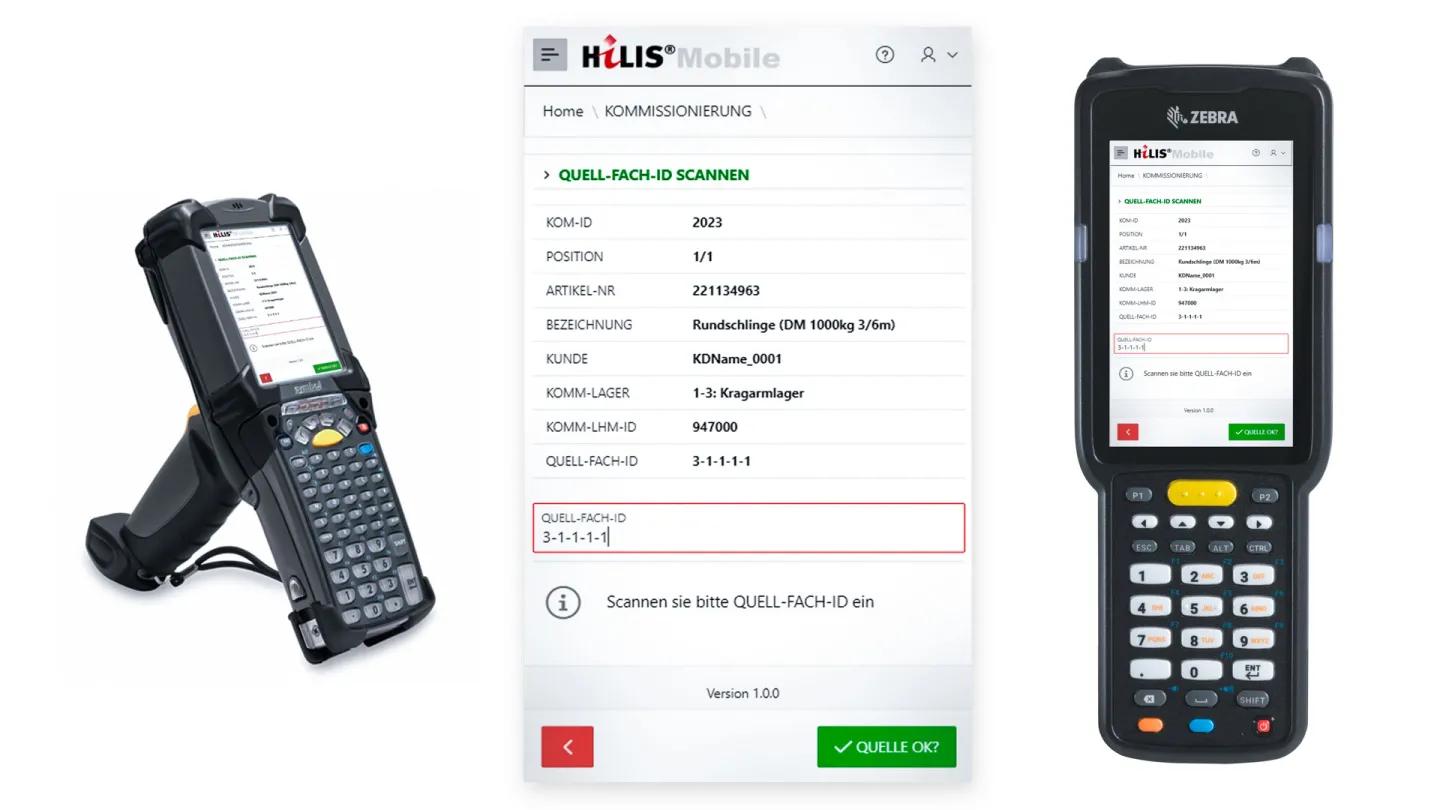

Order pickers use special-purpose handheld terminals to download their orders to the display of their mobile data acquisition device. Actual picking is confirmed by simply scanning a code or a touchscreen confirmation.

Pick-by-scan order picking systems rely on tablet PCs. Employees use MDE units (tablets) to handle their picking orders. A broad range of mobile device running up-to-date operating systems such as Android are available. Their display tells the picker the storage area and the items to be picked from there. To pick an item, the picker scans the barcode of the storage area and/or the item to ensure that it is allocated correctly.

In the picking process, the stacker control system’s (SCS) job is to optimise the order of picking orders and the truck routes. Part of the SCS is a central control module supplemented by terminals for communication with the trucks via WLAN. SCSs can be a component of your preferred warehouse management system (WMS) or a standalone system linked to that WMS.

Benefits of state-of-the-art voice and light-controlled order picking systems

Using automatic or automated order picking systems benefits you in many ways. They require neither teaching nor training, thereby improving the order pickers’ performance. They simplify the actual order picking process, thereby significantly improving the entire company’s productivity.

These benefits become particularly obvious when looking at up-to-date order picking systems by light or voice control and their outstanding improvement of picking efficiency at your site. Innovative equipment such as smart glasses, headsets or voice control ensure that your employees can move their hands freely, remain mobile and all that at a reduced risk of injuries and fatigue.

Benefits of automatic order picking systems in a nutshell:

- higher productivity

- faster order handling

- optimised picking precision

- improved workplace safety

- better customer service

We deploy our industry expertise and years of intralogistics know-how to support your use of cutting-edge order picking systems.

Sustainable order picking systems supplied by HÖRMANN Logistik

HÖRMANN Logistik provides you with a range of order picking systems you may operate as standalone systems for your logistics processes or linked to other units to make up an end-to-end solution. Let us be your partner to design tailored concepts for efficient order picking and sustainable processes.

HiLIS - Our Warehouse Management System is the heart of the intralogistics solution

Our HiLIS WMS is the core of the automatic or manual intralogistics process control system in the solutions we develop for customers, in our role as full service provider of custom intralogistics solutions. It's a high-performance software suite capable of mapping any process important to your intralogistics flows. As the central brain of the warehouse, HiLIS manages, controls and optimises both material and data flows.

HiLIS clearly displays all data on the user interface of your choice - whether it be a classic PC workstation or a mobile device. Our Warehouse Management System can even optimise, control and monitor complex customer-specific logistics processes. Moreover, its modular structure allows for custom adaptations to your specific needs, offering maximum flexibility and investment security.

The advantages of HiLIS offers:

- Flexible connection to any ERP and production systems

- All WMS functions

- Solution specific to AutoStore® systems: the HiLIS AS

- Imaging on mobile devices

- Clear and ergonomic dashboard

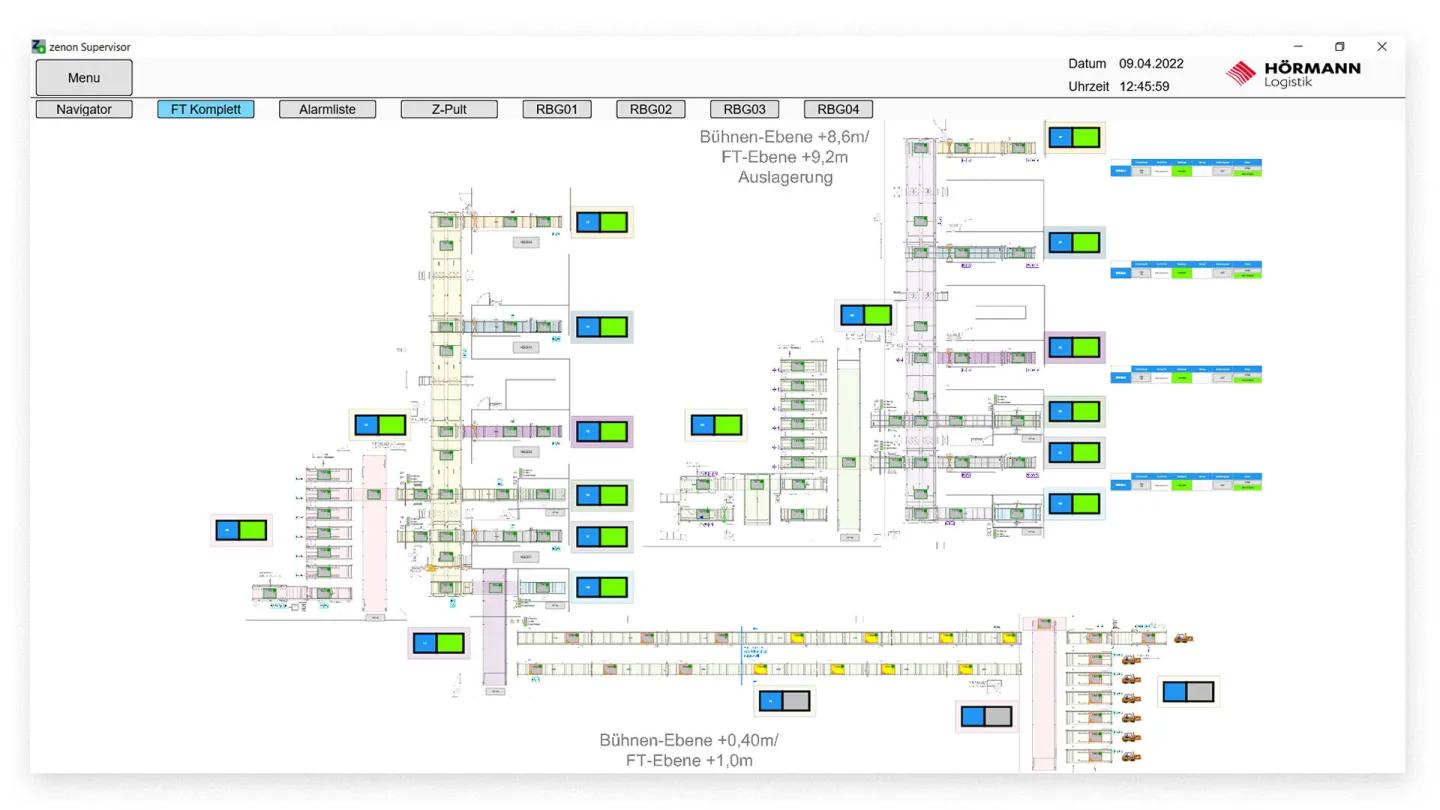

- Material flow control and monitoring

- PLC system integration

- Visualisation

- Maximum plant availability and flexibility

- Transparency and safety

- Scalable and future-proof

- Energy optimisation

AutoStore® small parts warehouse with connecting components for Richter + Frenzel in Reichertshofen

What is HiLIS?

A warehouse management system, or WMS for short, is software that automatically manages, controls and comprehensively maps all the processes of a warehouse and picking system, from goods receipt (or production connection) to goods dispatch.

Our Partner

We work with our partner HÖRMANN Pannon Software GmbH in Budapest, Hungary on the ongoing development of the HiLIS system. The company was founded in 1997 specialising in the planning and deployment of customer-specific software systems, from concept to commissioning and after-sales support.

The focus is always on the optimization of logistics, automation and production support systems.

High Performance, Ergonomic User Interfaces.

HiLIS is the ideal system for high-performance, flexible warehouse management. It centrally maps all subareas of your intralogistics from goods receipt to goods dispatch, optimising system coordination without media or interface inerruptions.

One of the most important aspects is that processes are not only controlled automatically with the option to intervene manually, but can also be optimally supervised by the warehouse staff.

In developing the user interface, as a provider of turnkey solutions we’ve exploited all aspects of our warehouse management system expertise. Intuitive, ergonomic operation, in addition to displays on attractive user interfaces, are fundamental prerequisities for frictionless, transparent processes.

»With HiLIS, we offer our customers a flexible, proven and future-proof warehouse management system for customised mapping and optimisation of individual intralogistics processes.«

PETER GIERLICH | PRODUCT MANAGER HILIS

HÖRMANN Intralogistics

Head of IT Solutions | HiLIS WMS

Peter Gierlich

Your HiLIS full-service provider - HÖRMANN Intralogistics

HÖRMANN Intralogistics is general contractor for all areas related to intralogistics. We continuously incorporate our comprehensive know-how and decades of experience in intralogistics into the development of our HiLIS-WMS.

Thanks to its modular, flexible structure and release-capable software architecture, HiLIS can be expanded at any time as your company grows, and quickly adapt to changing business processes. In other words, it’s a modern, flexible and investment-proof solution for you and your company.

Product details

HiLIS Warehouse Management Functions

- Warehouse and inventory management

- Master control

- Goods receipt and putaway

- Order control

- Replenishment and production supply processes

- Picking

- Consolidation and packing

- Shipping control

- Inventory

- Key performance indicators and reporting

- Material flow control

HiLIS Storage management

- Fully automated warehouse systems management (HRL, AKL, AutoStore®...)

- Manually operated storage area management: Person-to-goods picking warehouses, block warehouses, shelf warehouses, long goods / paternoster warehouses, etc.

- Storage zones division

- Chaotic and fixed storage space management, multi-deep

- Compartment and field load monitoring

- Capacity calculations and optimisation

- Multiple site management

HiLIS Inventory management

- Inventory management by item, item group, batch, QA status, BBD, remaining shelf life, loading aids, etc.

- Multi-level, segmented load unit mapping

- Flexibly combinable FIFO / LIFO / FEFO inventory management principles

- Automatic replenishment processes

- Set / kit item structures and parts list management

- Labelling and printing process management

- Serial number management

- Client capable

- Flawless traceability of all bookings and material movements, long-term archiving

HiLIS Inventory management

- Revenue from external and internal goods receipts

- Evaluation from ERP systems, production systems, external supplier systems

- Repacking and formation of loading units, at stationary and mobile workstations

- Additional storage and compaction

- Automatic warehouses: automatic identification and storage of loading units

- Manual warehouses: complete process mapping from collection to putaway

- Automatic destination warehouse assignment by HiLIS

- Plausibility checks (weight, dimensions, load carriers)

- Reporting of goods receipts including under- / over-delivery

- Control of QA inspection, clarification and release processes incl. photo documentation

- Flawless traceability of all bookings and material movements, archiving possible for years

Opening day control HiLIS

- Global order management

- Processing of external and internal order types

- Control of order priorities and rush orders

- Processing of orders according to staging times

- Sequenced retrieval and picking

- Control, synchronization and monitoring of transfer orders

- in all automatic warehouses and manual storage areas

- AGV / AMR, forklifts, tugger trains, ...

- Way optimization

Manual picking

- Goods-to-person

- Person-to-goods

- Serial / parallel picking

- Multi-level picking

- Multi-order picking

- Batch picking

- Negative picking

- Supported (mobile) picking technologies.

- Pick-by-Voice, Pick-by-Vision, Pick-by-Light

- Put-to-Light

- MDE, tablets, forklift terminals...

Supply and disposal of production areas

- Interface connection to production systems

- JIT and JIS production control/supply to KANBAN warehouses

- Supply and process control of tugger trains

- Possible integration of production processes in HiLIS

Supply and disposal of production areas

- Interface connection to production systems

- JIT and JIS production control/supply to KANBAN warehouses

- Supply and process control of tugger trains

- Integration of production processes in HiLIS possible

Consolidation and packaging

- Time- and status-controlled consolidation of order shares from different warehouse areas

- Cross-docking

- Process control in consolidation zones

- Mapping of all packing and shipping processes

- Calculation and application of volume-optimised packing schemes

- Packing instructions management

- Document printing (delivery bills, packing lists, accompanying documents, etc.)

- Shipping label printing, connection to shipping systems

Inventory

- Permanent inventory

- Zero-crossing inventory

- On-the-fly inventory discrepancy correction

- Near-zero inventory

- Inventory by item

- Inventory by key date

- Ad-hoc reporting of inventory corrections and inventory results to the ERP system

- HiLIS - ERP system inventory reconciliation

- Inventory list creation and editing

- Connection to external inventory systems

Systems engineering

- HiLIS application server operating system: Microsoft Windows Server

- Database: Oracle

- Programming language: JAVA

- Connection to all ERP, production and shipping systems via flexible interface modules

- Integration of all mobile terminals (MDE, forklift terminals, tablets, pick-by-voice, pick-by-vision etc.)

- Connectivity for "Industry 4.0" use cases such as predictive maintenance supported via standardised interfaces such as OPC/UA

PLC control engineering

- Communication with intelligent peripherals (Profinet, Profibus, Ethernet, OPC UA)

- Communication with actuators / sensors (AS-i technology, Profinet)

- Regular positioning with BPS, laser, camera system

- Continuous data tracking and runtime monitoring

- S7-1500 / 300 control system for materials handling and stacker cranes

- Step 7 / TIA framework for PLC programming

- System visualisation (SCADA)