Thank you for your Message.

We will contact you shortly. Sincerly, your team of HÖRMANN Intralogistics.

Find the right contact person for every area

Sales Manager corrugated cardboard warehouse

Mark Schulz

Director AutoStore Unit

Robert Heinz

Head of Robotic Solutions

Tom Walther

Sales Manager HL Polska

Pawel Lusiak

Head of IT Solutions | HiLIS WMS

Peter Gierlich

Managing Director HÖRMANN Klatt Conveyors

Florian Pöckl

Sales Director HÖRMANN Klatt Conveyors

David Leeb

Head of Retrofit / Customer Service

Christian Otterbeck

Head of Marketing HÖRMANN Intralogistics

Nina Maresch

How to find us

HÖRMANN Intralogistics Solutions GmbH

Gneisenaustraße 15

80992 Munich

T +49 89 149898-0

info@hoermann-logistik.de

Note: Unfortunately, we are unable to accept enquiries regarding possible cooperation/offers by telephone.

Please use our contact form or send us an e-mail.

Subsidiaries

HÖRMANN Intralogistics Austria

Since 2022, we can also be found in the "Logistics Valley" around Graz, Austria for our partners and customers. Sales Director Michael Hoffmann is your contact for local sales activities.

HÖRMANN Intralogistics Solutions Ges.m.b.H.

Grazer Str. 10

8130 Frohnleiten

Österreich

+43 316 228611- 510

info@hoermann-logistik.de

Registration court: Graz

Registration Nr: FN 572148 w | VAT ID: ATU 777 888 23

HÖRMANN Intralogistics Polska

HÖRMANN Intralogistics Solutions Sp. z o.o. was founded in May 2021 in order to be able to work the CEE markets more intensively. Pawel Lusiak is your contact person for local sales activities.

HÖRMANN Intralogistics Solutions SP.Z O.O.

Azymutalna 9

80-299 Gdańsk

Poland

+48 577 400 145

info@hoermann-logistik.pl

Registration court: Gdansk

Registration Nr.: KRS 0000903375 | NIP/ VAT ID: PL5842804782

HÖRMANN Pannon Software Kft.

HÖRMANN Pannon Software Kft. is an essential IT and development partner of the HiLIS warehouse management system, which maps customised solutions for individual customer requirements.

Meet HÖRMANN Intralogistics at these trade fairs and events

2024

2023

2022

2021

2020

2019

2018

2017

2016

Food & Beverage

The company

TOGETHER TO SUCCESS: Discover new opportunities for your future

At HÖRMANN Intralogistics, we are proud to be one of the most experienced system integrators for individual logistics solutions in a wide range of industries and to know exactly what our customers need. We achieve this thanks to the many years of experience, daily commitment and personal motivation of our employees.

What you can expect from us:

- Real team spirit with a feel-good atmosphere

- Flexible work organization options

- Transparent corporate governance

- Excitement for new technologies

- Numerous benefits such as company pension scheme "HÖRMANN Pension", job bike

This is what drives us every day. The high level of customer satisfaction encourages all employees in their outstanding work and motivates them to achieve new levels of excellence. Fair conduct is a matter close to our hearts.

As part of the HÖRMANN Group, we also want to take our responsibility for the climate, the environment and society seriously and make our contribution to achieving the 1.5 degree target by 2030 from the Paris Climate Protection Agreement. You can find our current Sustainability Report 2023 here!

Our values

Our company is growing rapidly. That's why we're looking for colleagues who want to develop our listening team, above all with energy, a sense of responsibility and an innovative spirit. This requires quality and reliability.

Together with you, we want to implement new digital solutions to become even more successful and further expand our market position. Move forward with HÖRMANN Intralogistics and apply ONLINE now for various positions in our team!

![]()

Drive

What we do, we do right - with maximum quality and reliability. We utilize the entire knowledge of the Group. We want to be proud of our performance.

![]()

Eye Level

We approach our counterpart with respect, whether it's a colleague, customer or partner. We behave fairly.

![]()

Responsibility

We make decisions in the interest of all. We act in solidarity. We think about tomorrow.

Innovative spirit

We think in terms of opportunities, technologically and entrepreneurially. Developments are possible for everyone. We want to improve every day.

Not found a suitable position? Take the initiative!

We are always looking for talented and motivated people who share our passion and bring a breath of fresh air to our team. Would you like to work for us, but there is currently no suitable position advertised?

References

Robotics

AutoStore® for compact, highly dynamic small parts storage and picking

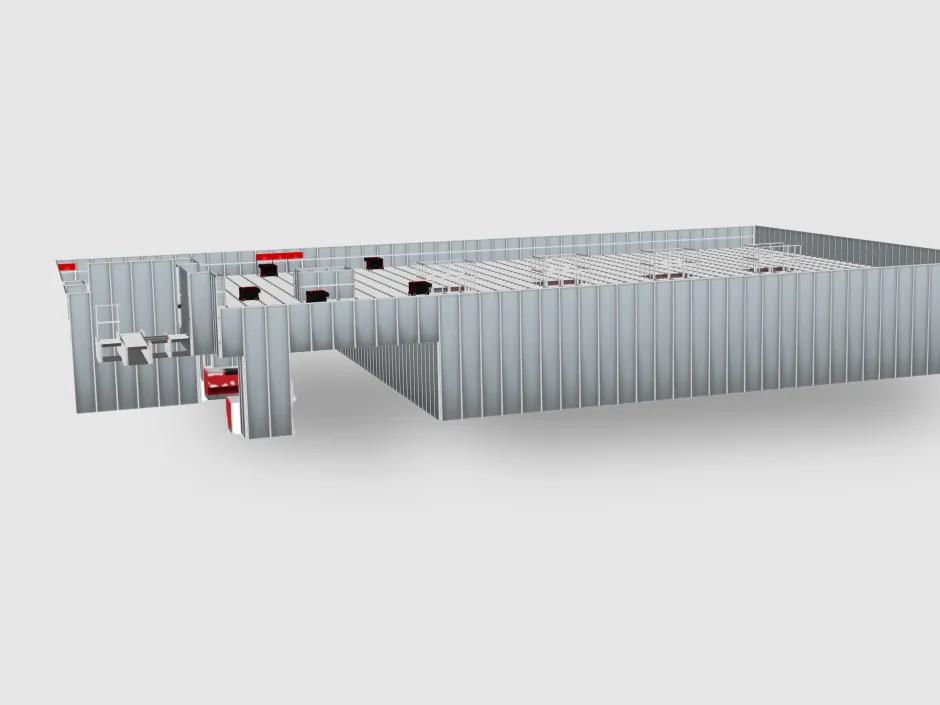

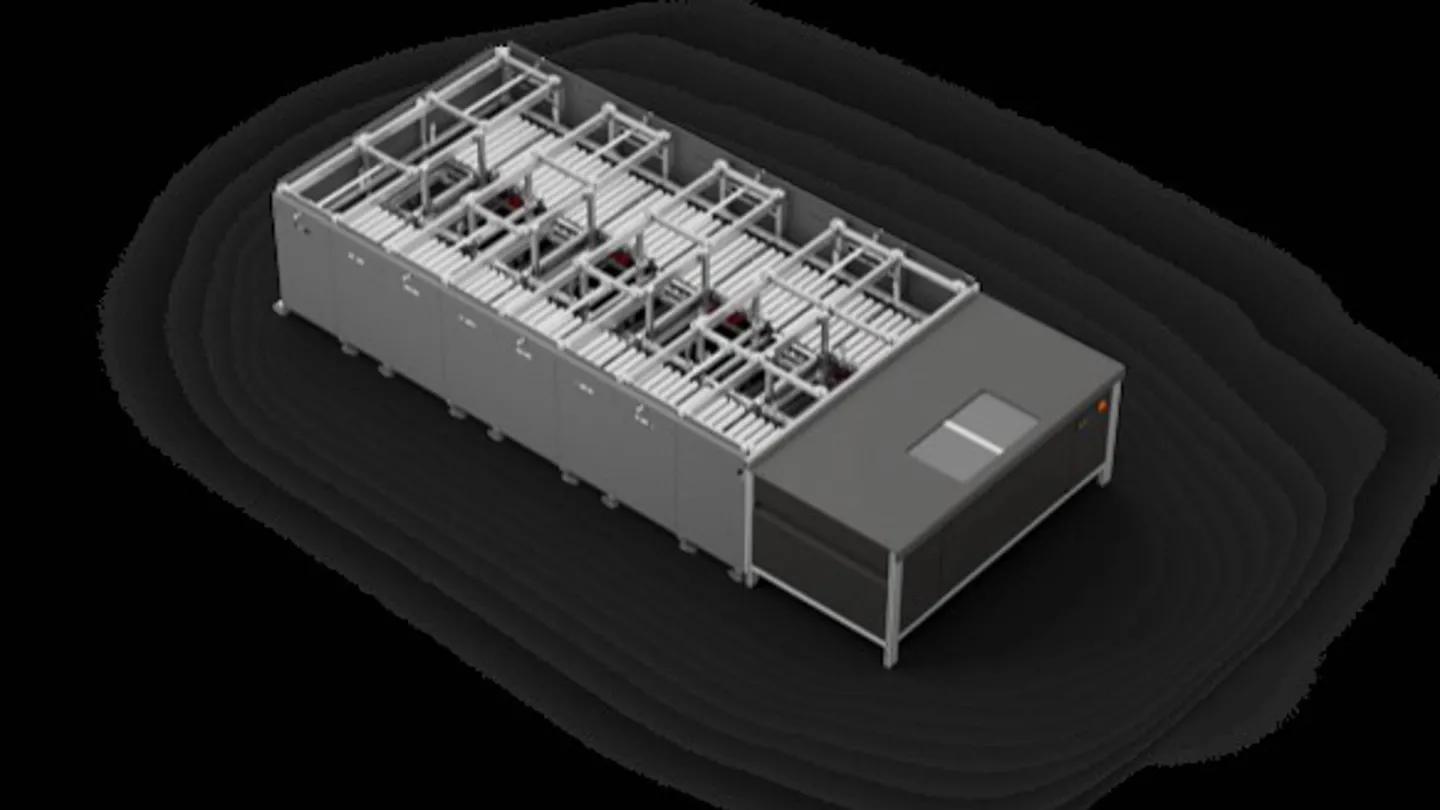

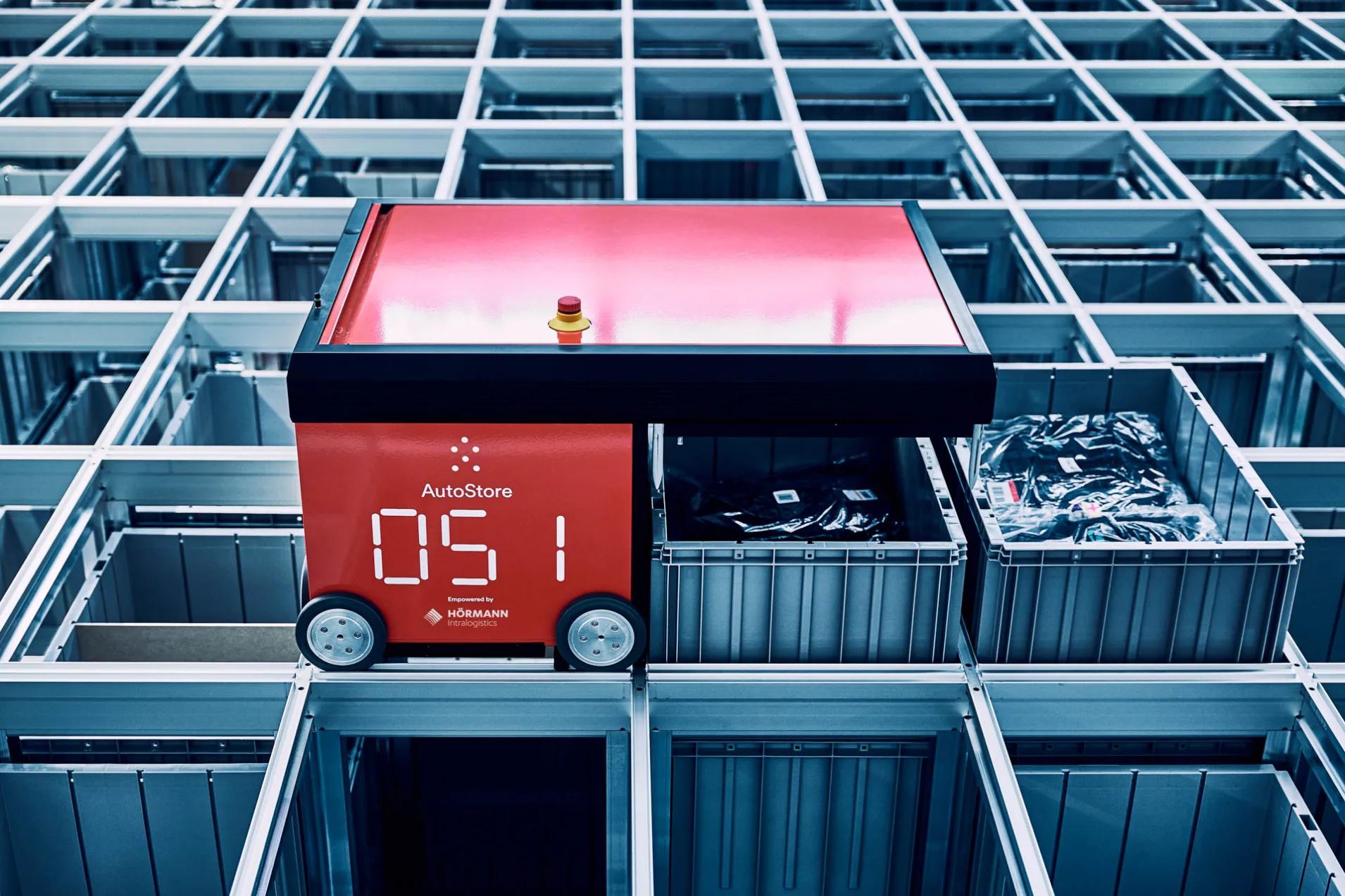

AutoStore® is an innovative, cutting-edge system for automated small parts storage and picking in plastic bins. This compact system optimises volume utilisation, dynamics, energy efficiency, expandability, material usage, and connections to picking stations.

As an official distributor, HÖRMANN Intralogistics offers AutoStore® with the HiLIS AS WMS tailored to it, along with all-round customer service as a general contractor.

The advantages at a glance

- Floor space reduced by up to 75%

- The Red& Black-Line robots tirelessly pick up bins, re-sorting and delivering them to the ports directly couple for receiving and picking goods.

- AutoStore® is a completely modular system, with throughput capacity determined by the number of robots and workstations.

- AutoStore® can be installed as a stand-alone solution or integrated into an overall logistics concept.

What it AutoStore®?

AutoStore® is an automated storage system that harnesses the power of warehouse robots for around-the-clock order fulfilment in a cubic layout so dense it can quadruple storage capacity and unlock the true potential of your warehouse space.

Our Partner

HÖRMANN Intralogistics is a long-standing distributor and system integrator of the world-renowned AutoStore® solution. In close partnership with the manufacturer, as general contractor we offer the CubeStorage system along with a specifically tailored HiLIS AS WMS, which is also capable of mapping manual storage areas and managing additional processes.

With the support of our trusted partners, we’ve already successfully implemented more than 50 groundbreaking automation solutions.

The solution in detail

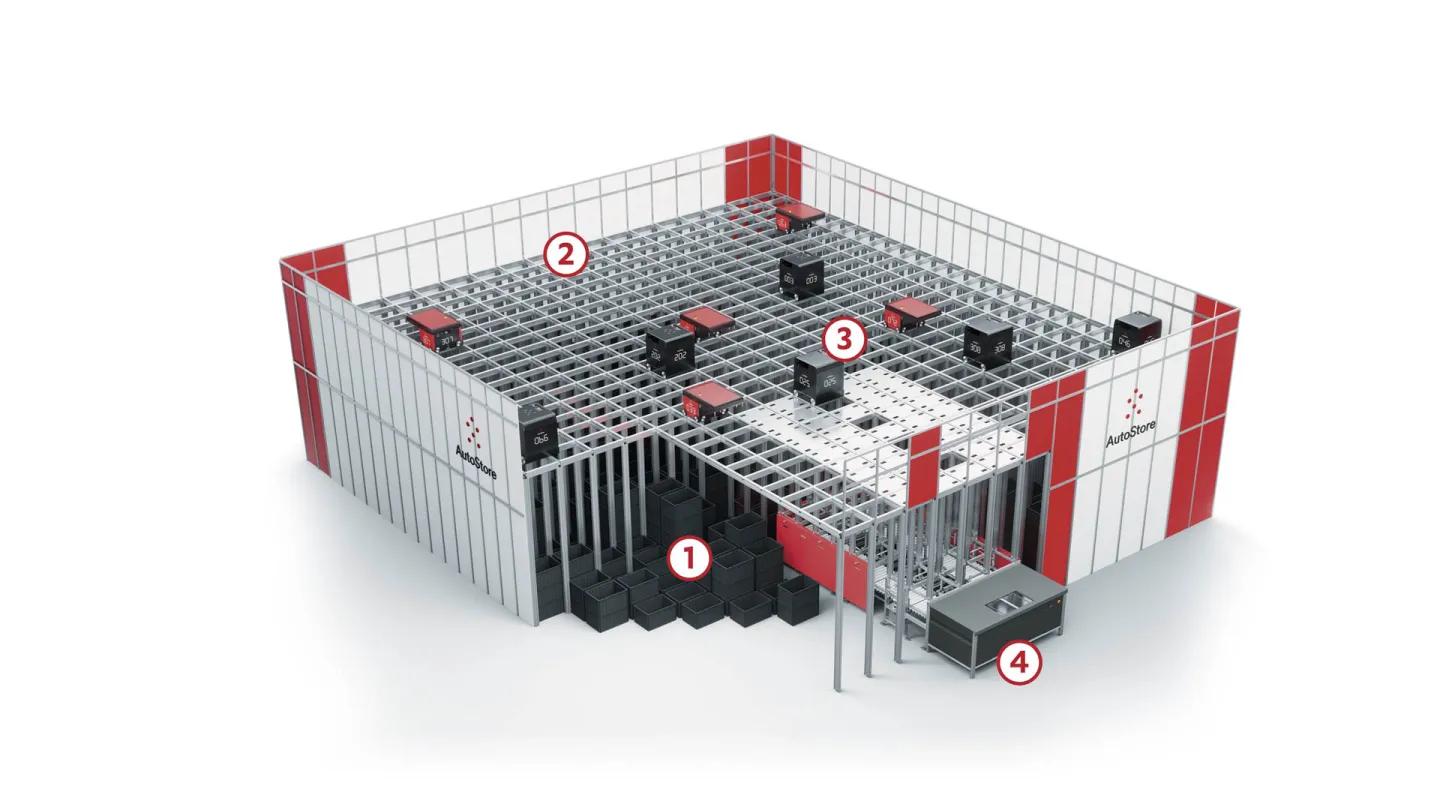

Bins

These sturdy and stackable bins, available in three different heights, can carry a maximum weight of 35 kg, and are also available in anti-static ESD version.

Grid

The self-supporting aluminum structure holds the bin stacks and guides the robots on the rails. Being modular, the grid can be arranged in any layout.

Red & Black Line line robots

With two pairs of wheels arranged crosswise, the AutoStore® robots can move in two directions, enabling them to reach any position in the grid to pick up, transport and set down bins.

Ports (picking modules)

Ports can be installed on all sides of the AutoStore® system and supplied by the robots without interruption. The ports are used for efficient picking and filling of the bins.

Controller

This module is the AutoStore® command, traffic control and database management centre.

AutoStore® in your warehouse - how it works:

- Bins

- Grid

- Robot

- Ports (picking modules)

-

Controller

- HiLIS AS Warehouse Management System

Download Whitepaper

E-Commerce & Logistics Systems of the Future

- Mega-trends & social discourses

- Fulfilment strategies at a glance

- Micro-fulfilment centres in detail perspective

- Practical examples from food to electronics

(in german)

Download nowPorts (picking modules)

Ports can be installed on all sides of the AutoStore® system and supplied by the robots without interruption. The ports are used for efficiently picking and filling the bins.

Depending on the type, the picking performance is between 160 and 650 items per hour.

- Maximum bin throughput - 400 bins/h on ground level, 500 bins/h on intermediate levels

CarouselPort - three-armed port

The CarouselPort works with three rotating arms, each one equipped with a bin pickup.

Maximum bin throughput:

- 350 bins/h average

- 500 bins/h theoretical maximum

ConveyorPort - straightforward workstation

The ConveyorPort uses a conveyor belt to bring bins to the operator. While one bin is presented to the operator, the second bin is held ready above the port by a robot.

Maximum bin throughput:

- 240 bins/h on an intermediate level

- 180 bins/h on the floor level

RelayPort - fastest possible bin availability

This modular workstation consists of the Touch picking module and buffer modules called tabs. Each picking station can have 3 to 6 tabs. The robots are able to reach the selected positions from any direction. With the TabSystem, robots fetch a bin back into the grid as soon as a bin is released.

Maximum bin throughput:

- 650 Bins/h

SwingPort - vertical connection

The SwingPort uses a rotating arm to deliver bins to the operator. While one bin is presented to the operator, the second bin is in waiting position at the opposite end of the arm.

Maximum bin throughput:

- 160 Bins/h mit 8 m BinLift

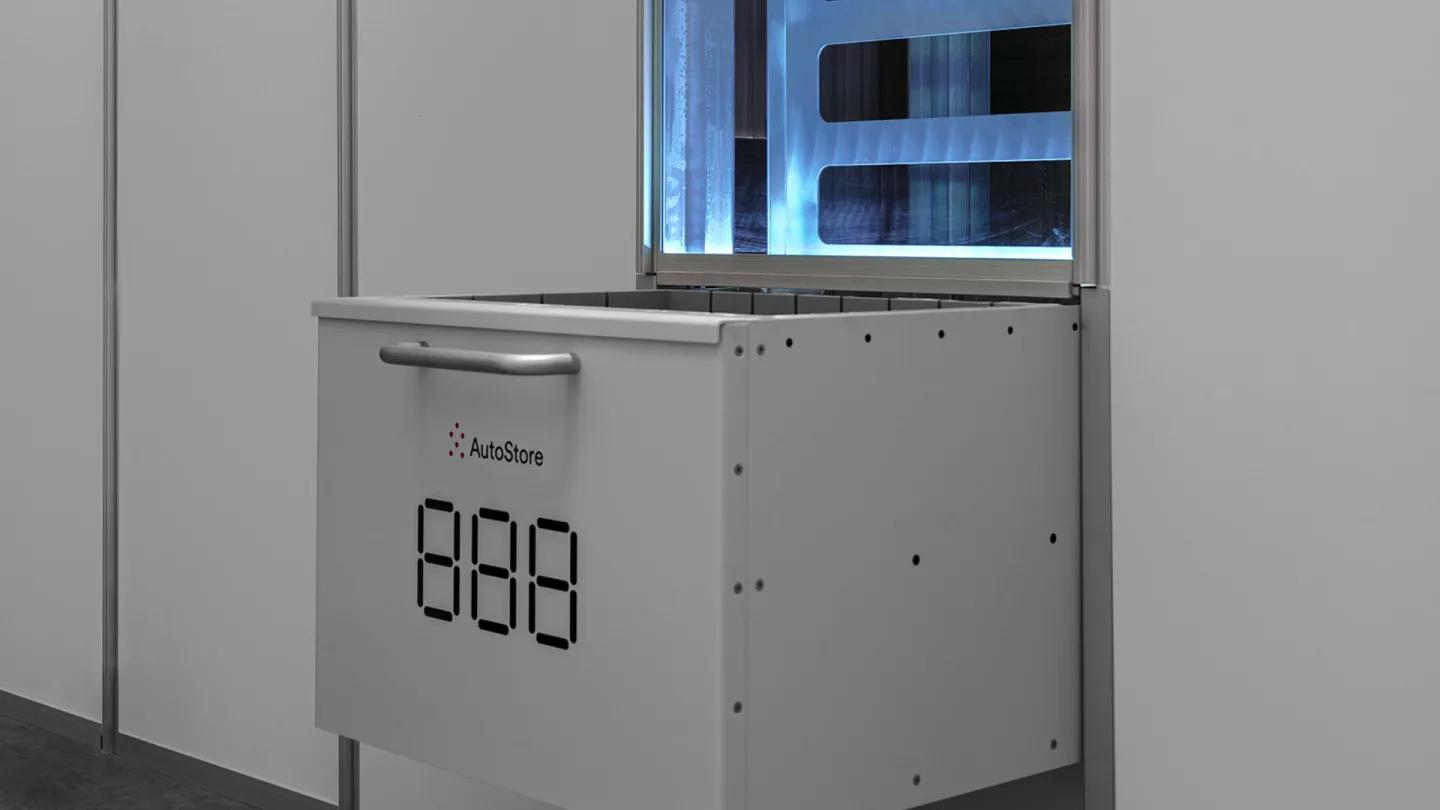

PickupPort - Automated end customer pickup station

PickUpPort is a public access point that enables contactless in-store pickup of online orders directly from AutoStore. With PickUpPort, retailers can easily and cost-effectively implement a BOPIS (Buy Online Pickup In-Store) omni-channel retail strategy, attract and retain customers, and ultimately increase sales.

The PickUpPort is available in narrow or wide versions and takes up no additional space next to the system when locked.

Contact us now

AutoStore® is custom configured according to your requirements, determined on the basis of simulations. Your quantity structures, item/order structure and performance requirements determine the size, number of robots and number of picking modules.

AutoStore® is suitable for both low performance and large bin capacity requirements, as well as highly dynamic requirements demanding several thousand storage and retrieval operations per hour.

Solutions and products for the future of intralogistics

Your partner for intralogistics, robotics, warehouse management and service

Along with renowned national and international partners, we develop innovative solutions and set new standards for intralogistics in terms of economic efficiency, performance and innovation.

Working to your advantage in five different areas

We are an attractive employment prospect for committed, performance-oriented people.

HÖRMANN Intralogistics - The Future of Intralogistics

Want to know more about HÖRMANN Intralogistics? Great! Just download our current brochure.