Reference Services

Automation of assembly lines for electric cars

The Services business unit operates as a highly specialized industrial service provider. As a recognized partner to the automotive industry, mechanical engineering and other branches of industry, we take on a wide range of tasks in the life cycle of a production plant - from planning and project planning to the assembly of machines and the construction of turnkey plants to commissioning and condition-based maintenance.

The competencies of HÖRMANN Intralogistics Services include the entire necessary range of services:

- Mechanical design including steel construction

- Pneumatics and hydraulics

- Comprehensive electrical distribution design

- Digital networking

- Programming of robots

- Visualization

With an experienced team of skilled workers and specialists, HÖRMANN Intralogistics Services also takes responsibility for the installation of new production facilities, right through to commissioning and support during production start-up. One special project was the planning, installation and commissioning of the entire media installation in the assembly plant of an OEM: In order to reduce the high costs for the development of electric cars suitable for mass production, the customer developed the modular e-drive system (MEB) as a new technology platform.

Highly automated and digitally networked production facilities are also needed to enable cost-effective production of steering components in high volumes.

We provided the customer with intensive support for the entire media supply for compressed air, cooling water, and lubricants in the form of oil and grease, and assumed responsibility from project planning to procurement to commissioning, including shift support during the start of series production.

Some data - 51 robot grippers, 633 cylinders, 550 individual valves, 800 meters of media supply and cable duct ¬ were installed on an area of around 1,600 square meters. After twelve months, the plant was successfully commissioned.

OEM reference

Increased cycle times for more productivity

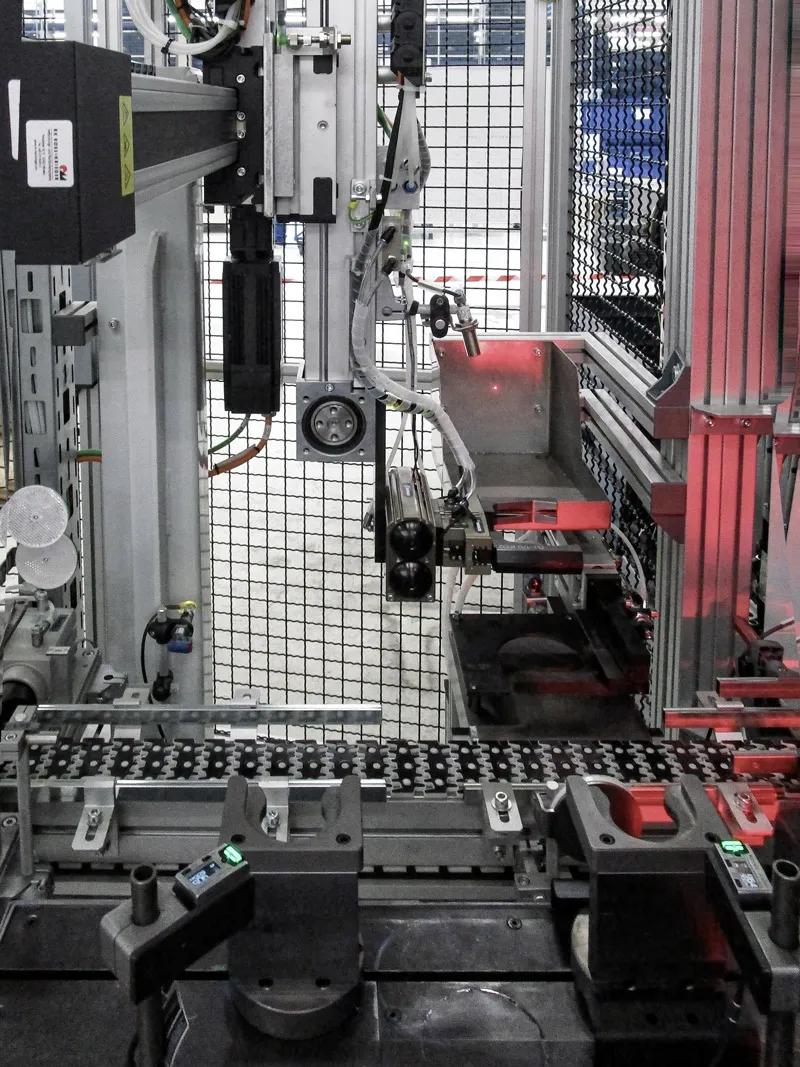

HÖRMANN Intralogistics Services carried out an increase in cycle time and optimization of the workplace in the assembly plant of an OEM, taking into account ergonomic and ecological aspects. With the customer a concept was developed, which improves the loading and unloading of two parallel machines for processing components.

The components had to be deposited in the machine beforehand via loading gantries. Loading and unloading could only take place one after the other: first machine 1, then back and forth, and then machine 2. After unloading, the loading gantries had to make an empty run back into the component removal area to be loaded with a new component. During this process, the machine was unable to continue processing a component - this led to high downtimes.

This process is now carried out by two robots that can load both machines in a staggered manner. The transport distance was reduced by a smaller swivel radius from component removal to placement. The components can now be transported in parallel and simultaneously. There are no more waiting times.

"With the new concept, we created short distances and lower costs due to downtimes for machine and line operators with up to a threefold time improvement"

GERHARD JACOBI | EXECUTIVE DIRECTOR

Good reputation leads to follow-up projects

"The customer commissioned the project from us not only from an economic point of view, but also because of our experience and our good references in the field of automation," Gerhard Jacobi continues. Another plus point was that there were no interface problems, as HÖRMANN Intralogistics Services was able to offer the entire project from A to Z - from planning, concept development, design, data backup, automation to mechanics and electrics. Thanks to the year-round presence on site, the HÖRMANN Intralogistics Services employees were immediately available in case of adjustments.

So immediately afterwards, the customer commissioned another project to improve component production. In the future, the handling of the shopping baskets on the cockpit assembly lines, which contain components and are transported to logistics by a sequence trolley, will also be handled by robots. In the past, the baskets were loaded by hand - this often led to time problems and, as a result, downtime in final assembly.

"The baskets are now fully loaded just-in-time at the assembly lines, matching the corresponding vehicle"

GERHARD JACOBI | EXECUTIVE DIRECTOR

All-round service for a smooth process

The design and fabrication of the gripper technology for the robot was created by the employees of HÖRMANN Intralogistics Services. Through a Robcad survey, the positions of the robots and the new work area were determined. Planning was followed by assembly and installation with robot consoles, energy supply, media supply, lighting, cabling, pneumatics and grippers.

Tailored for the customer, a steel maintenance platform was fabricated and assembled with access, stairs, railings and guards, as well as light barrier technology. Then followed the programming and commissioning of the robots as well as the coordination of the internal interfaces of the robots to the plant. "We basically accompany the production for a few weeks in order to eliminate possible malfunctions directly and to train the plant operators on site during operation," says Gerhard Jacobi.

References

Services

Reference NTN Drive Technology

Reliability at the right pace during transport through series production

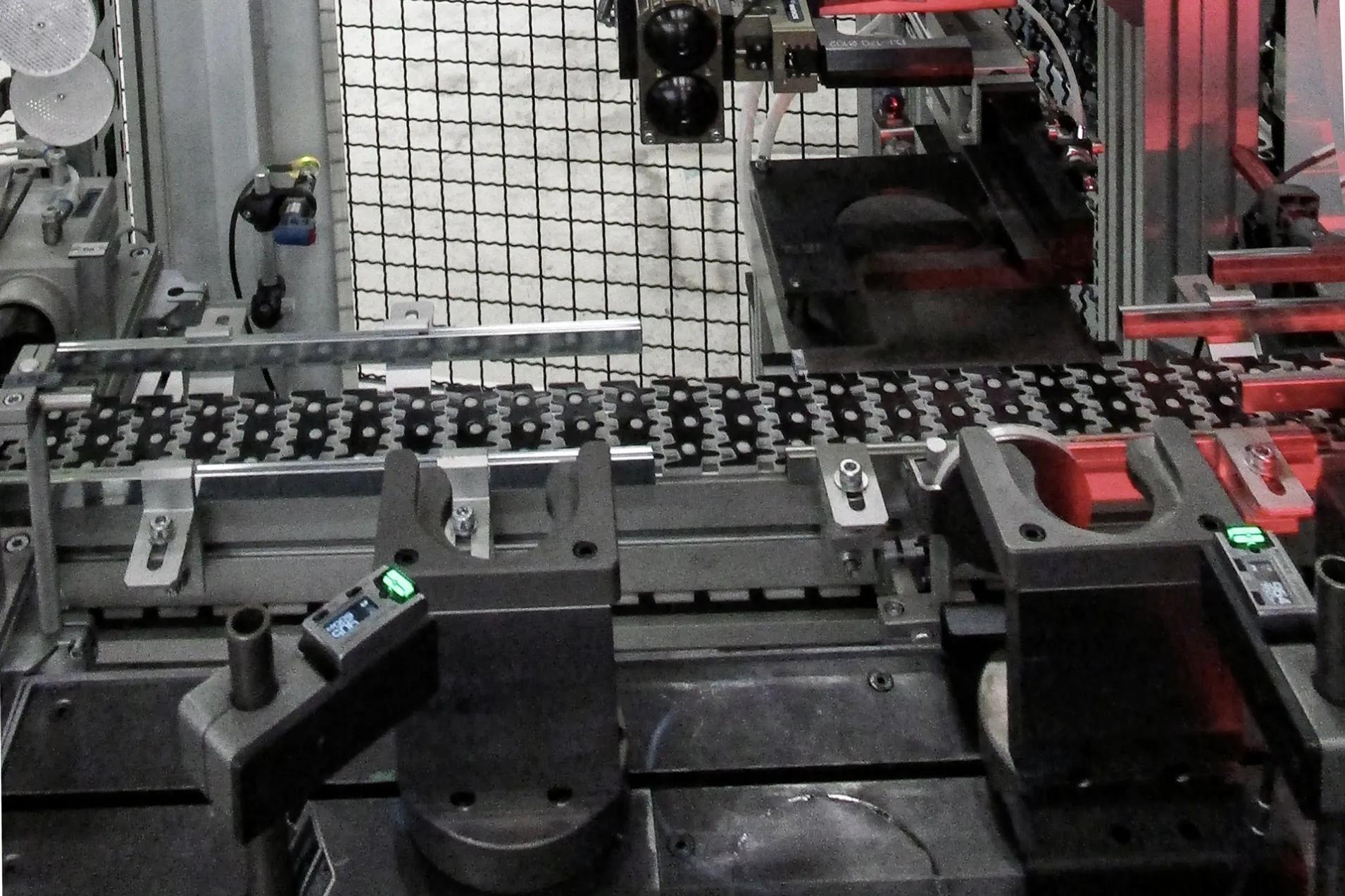

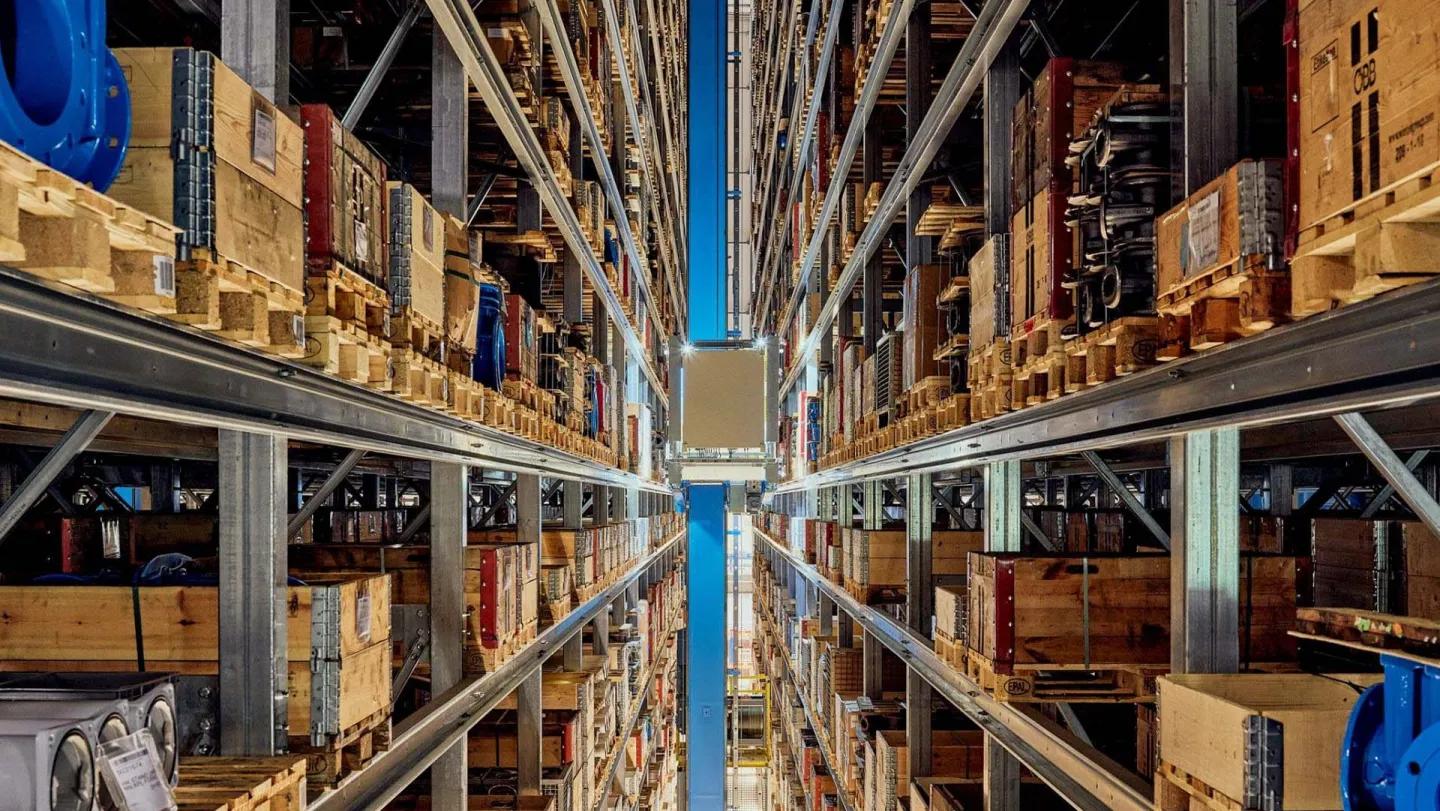

For the assembly of a modern automobile with an internal combustion engine, up to 10,000 components are required, which are produced in highly automated, clocked production lines with a high number of processing stations and a wide variety of manufacturing processes. To ensure high economic efficiency of these production facilities associated with multi-million investments, the reliable transport of components from station to station in the right cycle is of particular importance.

NTN Antriebstechnik GmbH in Gardelegen (Saxony-Anhalt), a subsidiary of the Japanese NTN Corporation, is a leading global producer of drive shafts for the automotive industry and a supplier to well-known German car manufacturers. In connection with the construction of two new production lines, NTN commissioned HÖRMANN Intralogistics with the interlinking of the individual processing stations. In this project, demanding goals had to be realized: a line cycle of 36 seconds and an output of 800 parts per shift.

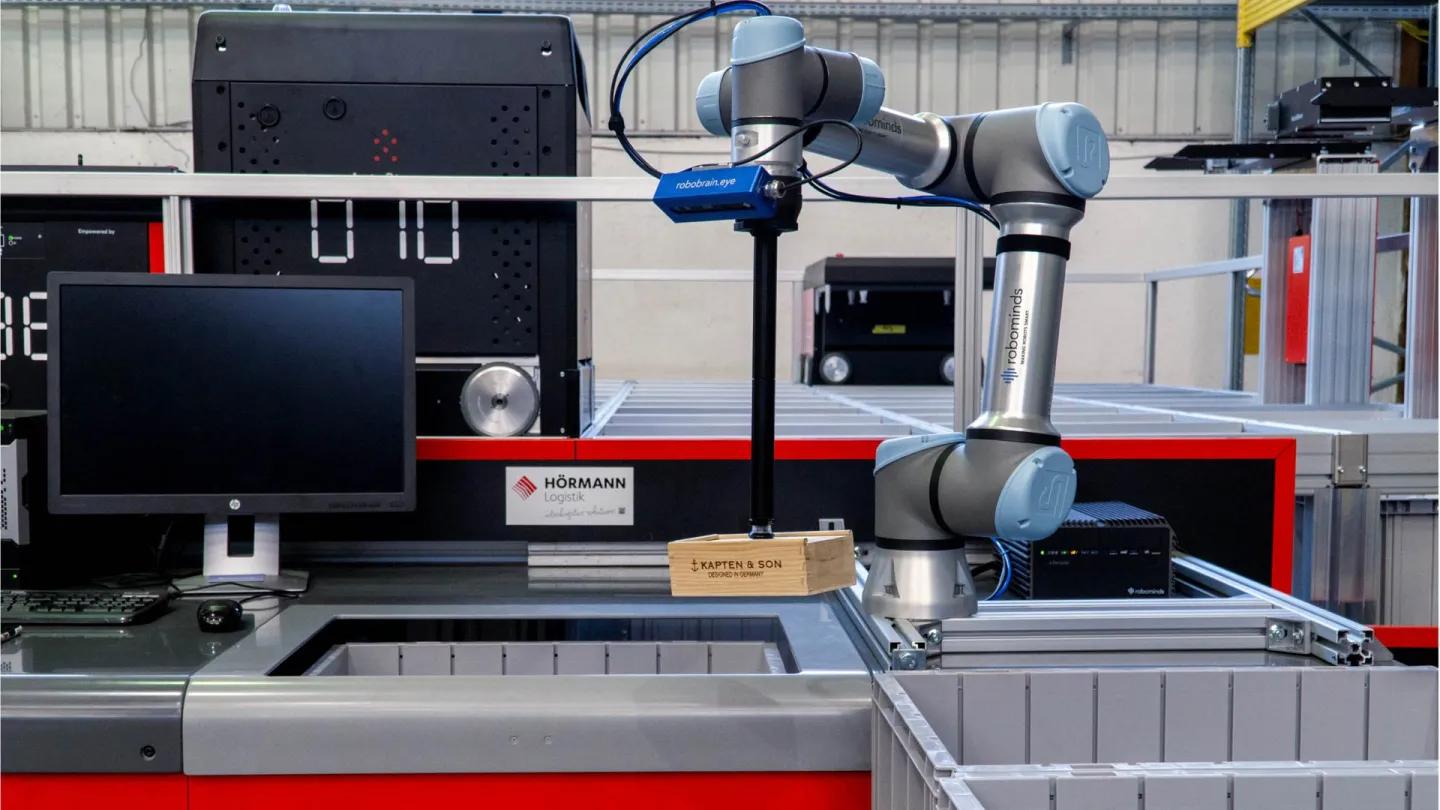

Turnkey automated production systems from a single source

HÖRMANN Intralogistics created the plant layout, the mechanical design of the linkage, and the automation concept, including electrical planning. At the heart of the interlinking are the hinged chain conveyors, the loading gantries/stations that transport workpieces weighing a maximum of 2.2 kilograms. Particular challenges in the project planning were the integration of a tempering furnace for heat treatment of the workpieces and the guarantee of a travel path in the production by means of a lifting/lowering station.

The installation of the mechanical components, all protective devices and the electrical installation were carried out by HÖRMANN Intralogistics Services GmbH, a business unit of HÖRMANN Intralogistics.

The automation technology and software developed in-house ensure precisely timed control of the entire transport from station to station with a high level of availability, whereby each production line has a separate control system with a high number of protective circuits. Numerous services accompanying the product, such as the inspection of electrical equipment in accordance with DGUV 3, training of operating and maintenance personnel, commissioning of the system, support during the start of production, as well as the usual documentation, operating instructions and maintenance plans, complete the scope of services provided by HÖRMANN Intralogistics.

After several changes in the parts spectrum, the successful commissioning of the entire production plant took place at the beginning of 2020.

HiLIS Warehouse Management System

Process optimisation lies in the details

Our HiLIS warehouse management software brings all processes together, but only with a really close look into the subareas of the intralogistics process do all the other advantages become clear. The perfection of the overall process depends on every small step. Achieving systemic, all-encompassing optimisation means planning each of them down to the smallest detail. We’d like to shed some light on these for you in the paragraphs that follow.

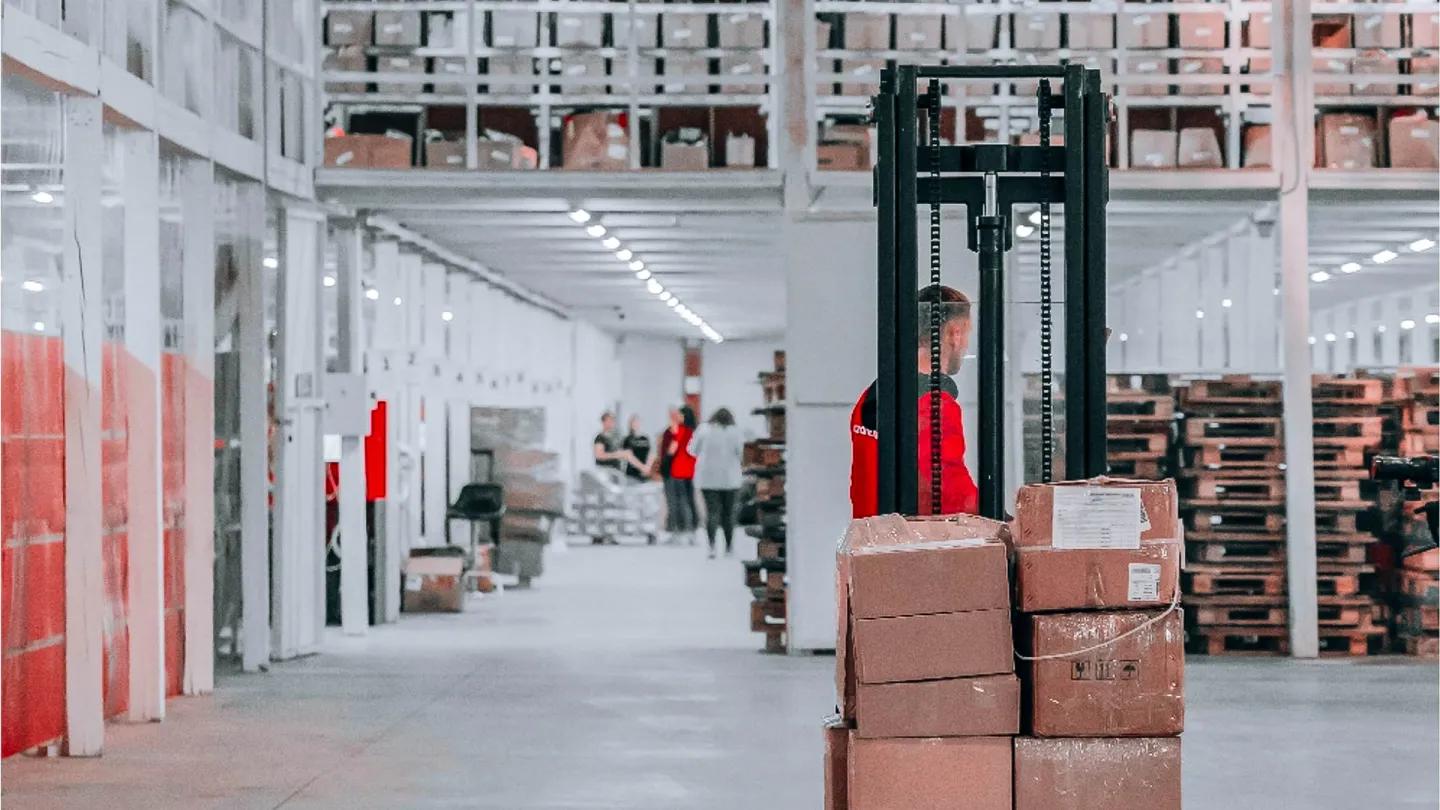

Goods receipt - admission to system

The HiLIS processes goods receipt based on notifications from the ERP system. Through this process, incoming goods are entered into the system, generating technical data on the formation of loading units to be handled by staff

Our WMS distributes the goods for putaway in different storage areas according to flexible sets of rules. The automatic or manual putaway processes follow sophisticated putaway strategies that optimize warehouse volume utilization and significantly reduce retrieval and picking cycle times.

Load units are automatically identified and measured prior to storage in our automated storage systems and, if necessary, labelled accordingly. This process also includes plausibility checks to detect obvious errors in the goods receipt process at the earliest possible stage, and enable the appropriate response. Measurement prior to storage also contributes to maximum space-optimised use of all storage areas under management. Since space is one of the most important cost factors, every millimetre that can be utilized based on the Tetris principle means money saved.

Warehouse administration and inventory management

Our Warehouse Management System can be custom-made and tailored to your needs, and we can provide flexible solutions for both manual warehouse management and fully automated warehouse/material flow processes, like AutoStore® for example.

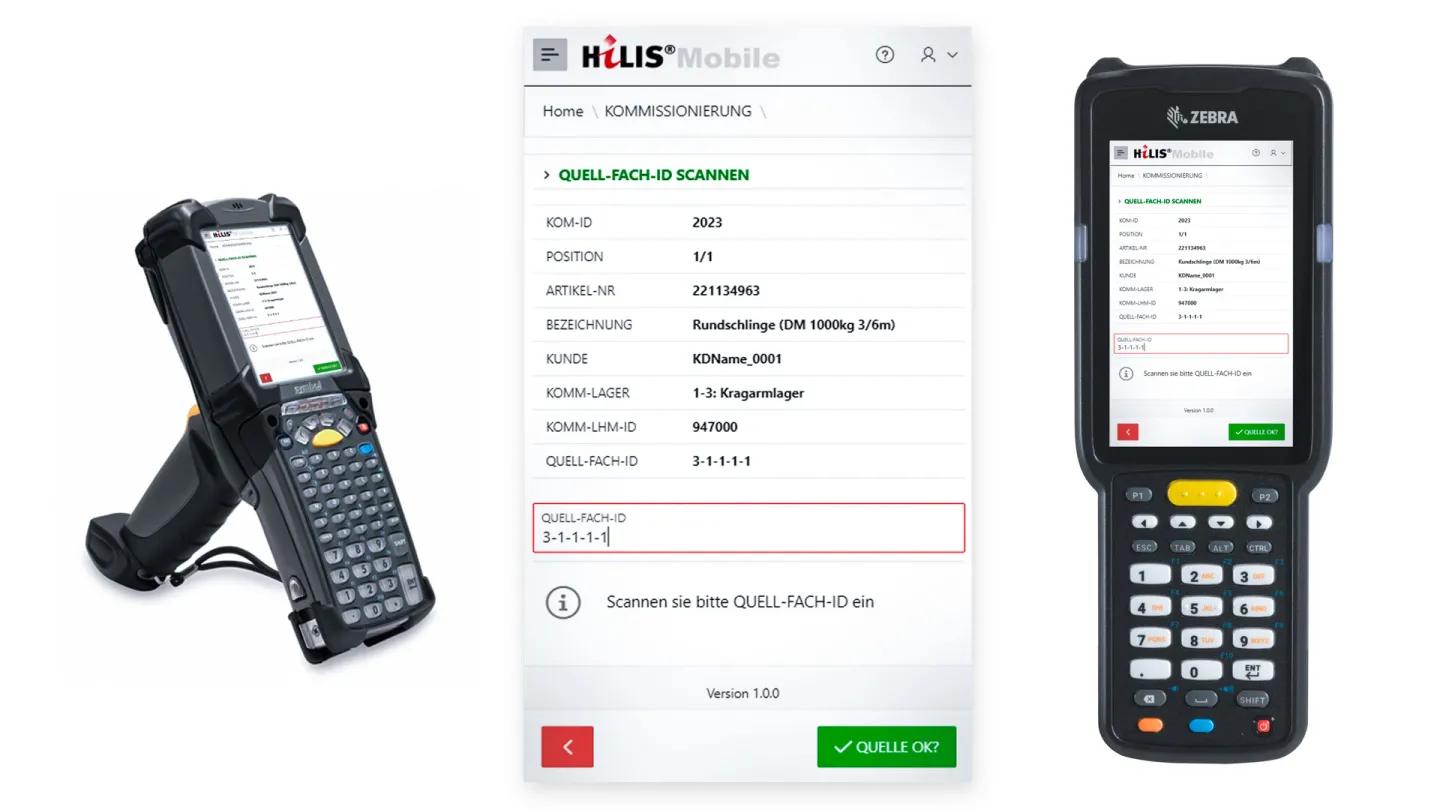

A particular advantage HiLIS is that it’s compatible with terminal devices (MDE, printers, wearables, forklift terminals, pick-by-voice, etc.) made by a wide range of manufacturers, which can connect to our WMS via flexible interfaces. We can even integrate the end devices used in your existing warehouse facilities, further increasing sustainability.

HiLIS warehouse management offers comprehensive management functions based on elementary inventory attributes, like batches, MHD and serial numbers. It is client-capable and can map the respective status in quality assurance. It supports any warehouse management strategy, like FIFO, LIFO, and FEFO, for example. All warehouse logistical transactions can be documented and archived, even for several years if necessary, permitting continuous traceability.

Replenishment management operates according to minimum stock target markers in all storage areas managed by the WMS. This way, the TARGET stocks are automatically monitored and, when stock falls below the parameterizable target marks, replenishment orders are automatically issued according to the corresponding sets of rules.

Order processing and picking

The outbound path of goods from the warehouse begins with a retrieval or picking order. Our HiLIS warehouse management system can receive orders from an ERP system, a web store or a production control system (MES) for example, and initiate the corresponding processing. At this stage, order management can flexibly controlled according to type, priority, predefined staging and loading times, and the organisational processing areas available in the warehouse. To optimize the process, orders can even be split into smaller packages for distribution by a number of workers.

To meet individual requirements, order picking can be implemented based on a wide variety of combinable techniques, such as:

• Person to the goods

• Goods to person (optimised path)

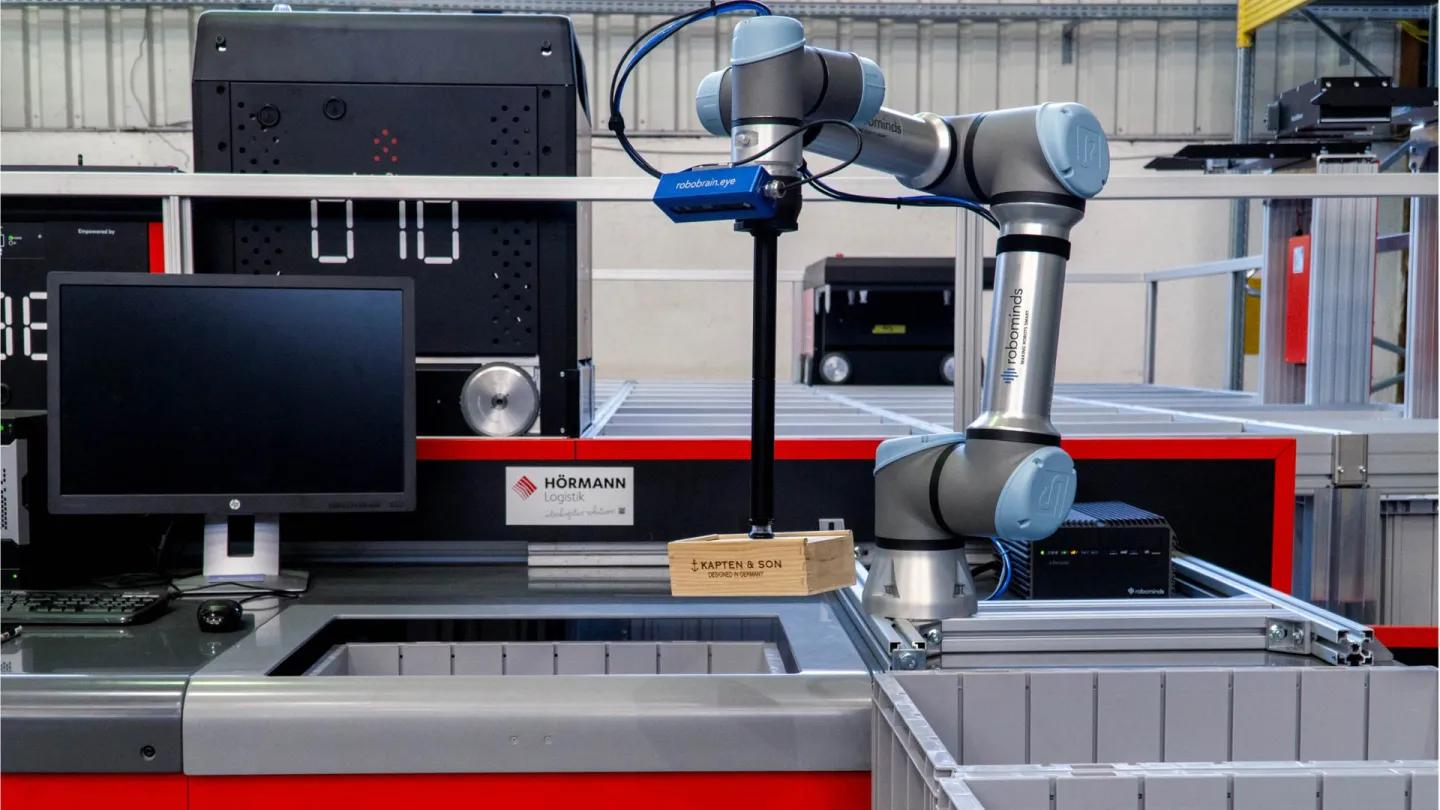

• Pick-by-robot

• Pick-by-Voice

• Pick-to/by-Light

• Batch and wave picking

• Multi-order picking

• Multi-level picking

• Negative picking

Process flows can be mapped on both stationary and mobile terminal devices. Items picked from the various storage areas for an order are collected in consolidation zones managed by the HiLIS.

This particular process is one of the key tasks of the WMS in order management, because it enables precisely timed dispatch of picking and retrieval orders to the various storage areas, so that all portions of an order promptly arrive in the consolidation at the same, ideal time. With intelligent algorithms and other fine-tuning controls customers can adjust by themselves, our HiLIS Warehouse Management System manages this task excellently.

Packing and shipping

In terms of package generation and packing, HiLIS provides well-tried and tested process flows controlled by intuitive user interfaces, and flows can be mapped on both stationary and mobile devices. Our WMS is capable of covering all aspects typical of the packaging process, from booking into shipping boxes or onto large load carriers, to printing packing lists, delivery bills and shipping labels, and on to customer-specific packaging specifications and value-added services.

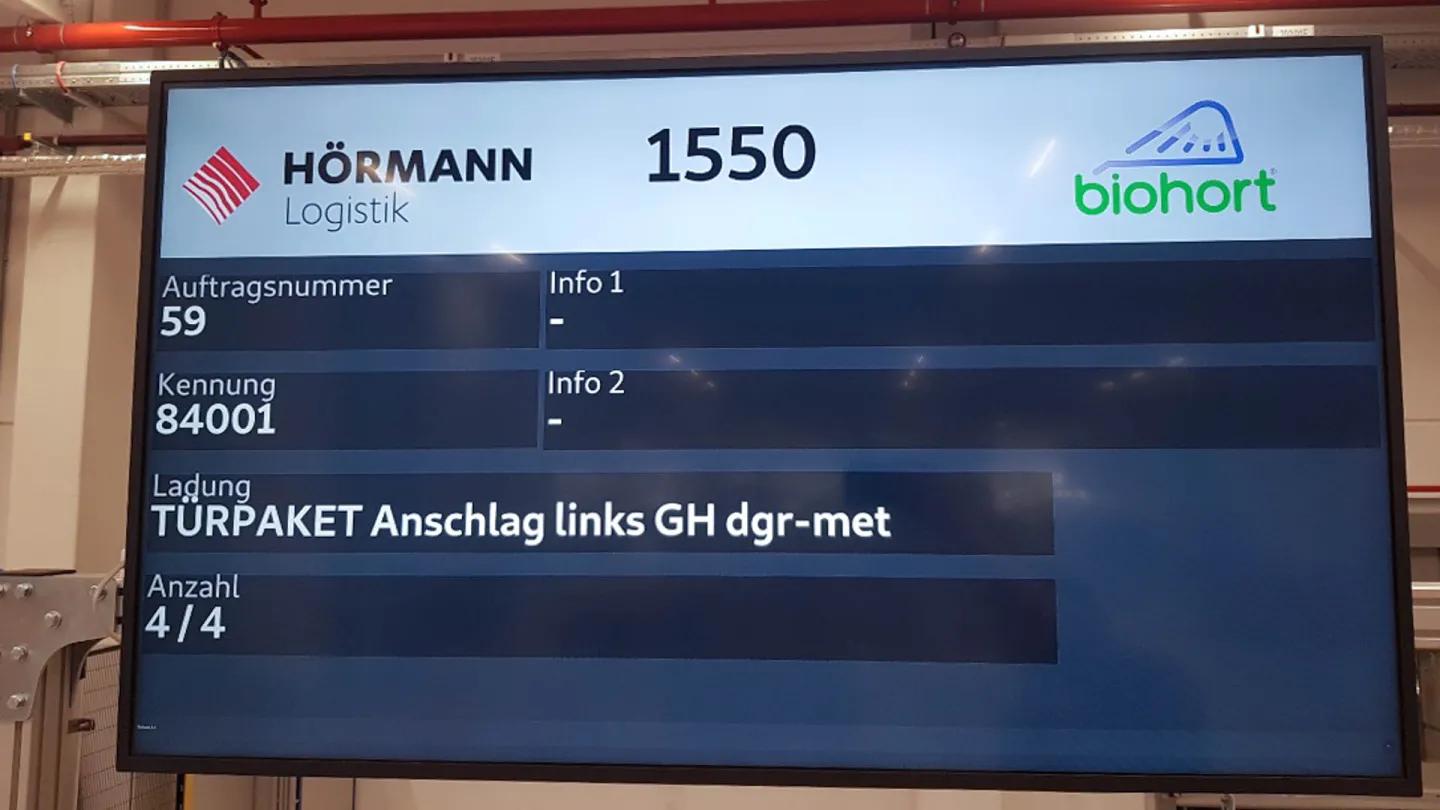

Truck loading control

Loading management is the central module of the HiLIS. In this module, truck tours can be managed or even compiled from individual customer orders, to initiate and subsequently control truck-specific loading. Sequenced retrieval from automatic high-bay warehouses or dispatch to manually operated loading zones is another key process, where trucks have to be loaded precisely to the unloading point according to a predefined sequence. The HiLIS Warehouse Management System controls loading and pallet accuracy, and provides workers with a wide range of control and help functions for error-free and rapid truck dispatch, like load carrier NVE scanning and large displays installed in the loading zones.

At this point, the goods leave the intralogistics system. All transactions up to this point, from the customer-specific reservation of goods to the completion of a truck tour load, are logged and archived in the warehouse management system. This ensures continuous traceability for each individual customer order.

Inventory in Warehouse Management

Inventory is an important part of intralogistics management, and our HiLIS warehouse management system permits continuous inventory management. Inventory changes detected by employees in the course of the logistics process are reported in real time to the higher-level ERP system, enabling maximum transparency. The system also supports periodic inventory procedures, like by-article and key date. The results can be displayed, stored and further processed in corresponding lists, and the inventory reported to the ERP system.

Optimized material flow control

The integrated HiLIS material flow control ensures efficient and synchronized transport order processing. Whether in the form of a stacker guidance system, an integrated AGV system or fully automatic control goods flow in automatic high-bay or small parts warehouses with connected conveyor technology, HiLIS stands for highly dynamic and flexible control of your material flows.

In automated warehouse systems, connection of PLC controls (also supplied by HÖRMANN Intralogistics) to the material flow control system is via a standard interface well-tried and tested in many customer facilities. In keeping with our credo: all you need from a single source.

Warehouse Management User Displays and Interfaces

One of the highest priorities of out Warehouse Management System is the user interface. To offer maximum efficiency and easy onboarding of new workers, all interfaces are designed for easy working dialogue. The HiLIS software offers optimal process monitoring, ergonomics and intuitive operation.

This also allows for central mapping, as well as access to all functional areas, enabling rapid diagnosis and reaction to any malfunction. The user interfaces can be mapped on both stationary and mobile devices.

Maximum efficiency

This concerted interaction of all logistics sub-processes offers remarkable potential for optimising the entire intralogistics process. The possibility of connecting the WMS directly to external systems, like web stores or transport management systems (TMS), makes it possible to digitalise, automate and integrate intralogistics even further.

Our HiLIS Warehouse Management System saves space and time, and so reduces costs. Our Warehouse Management System offers enormous increases in intralogistics performance, especially in combination with automated storage, conveying and picking technology. We can develop the solution for your individual requirements, and custom build it as well, all from a single source. HiLIS makes your processes more efficient, clear, easy to plan and flexible, enabling you to react faster and better to change, and make life a lot easier for your staff.

HÖRMANN Intralogistics with HiLIS - Your full-service provider

HÖRMANN Intralogistics operates as a general contractor in all intralogistics-related areas. We are constantly incorporating our comprehensive know-how and decades of experience in intralogistics into the development of our HiLIS-WMS. We’ve thought of everything, and offer you a mature WMS solution for planning, controlling and monitoring your intralogistics, with performance proven time and again in countless customer projects of all sizes.

Thanks to its modular, flexible structure and release-capable software architecture, HiLIS can grow as your company grows, and quickly adapt to the changing business scenario.

In other words: a modern, flexible and investment-proof solution for you and your company.

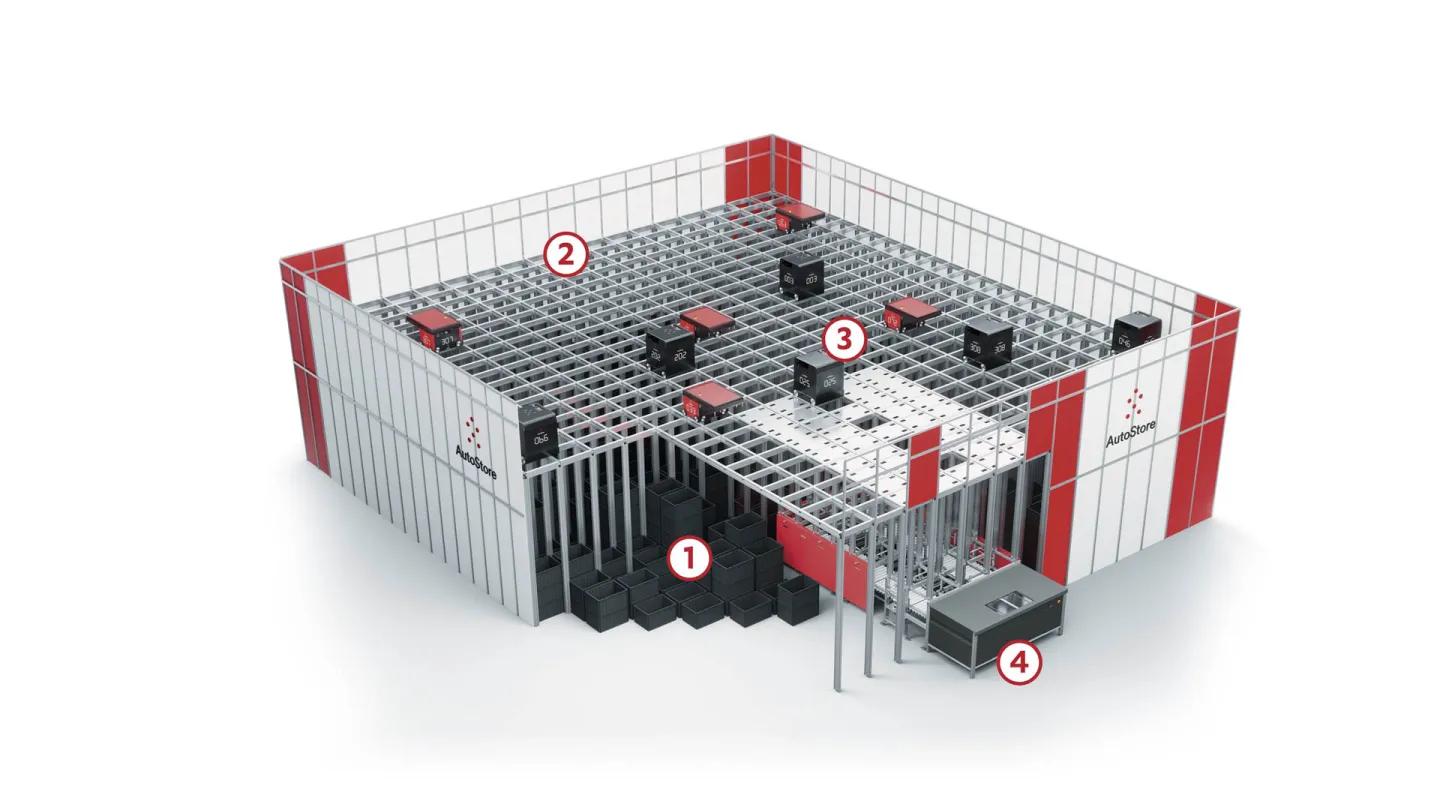

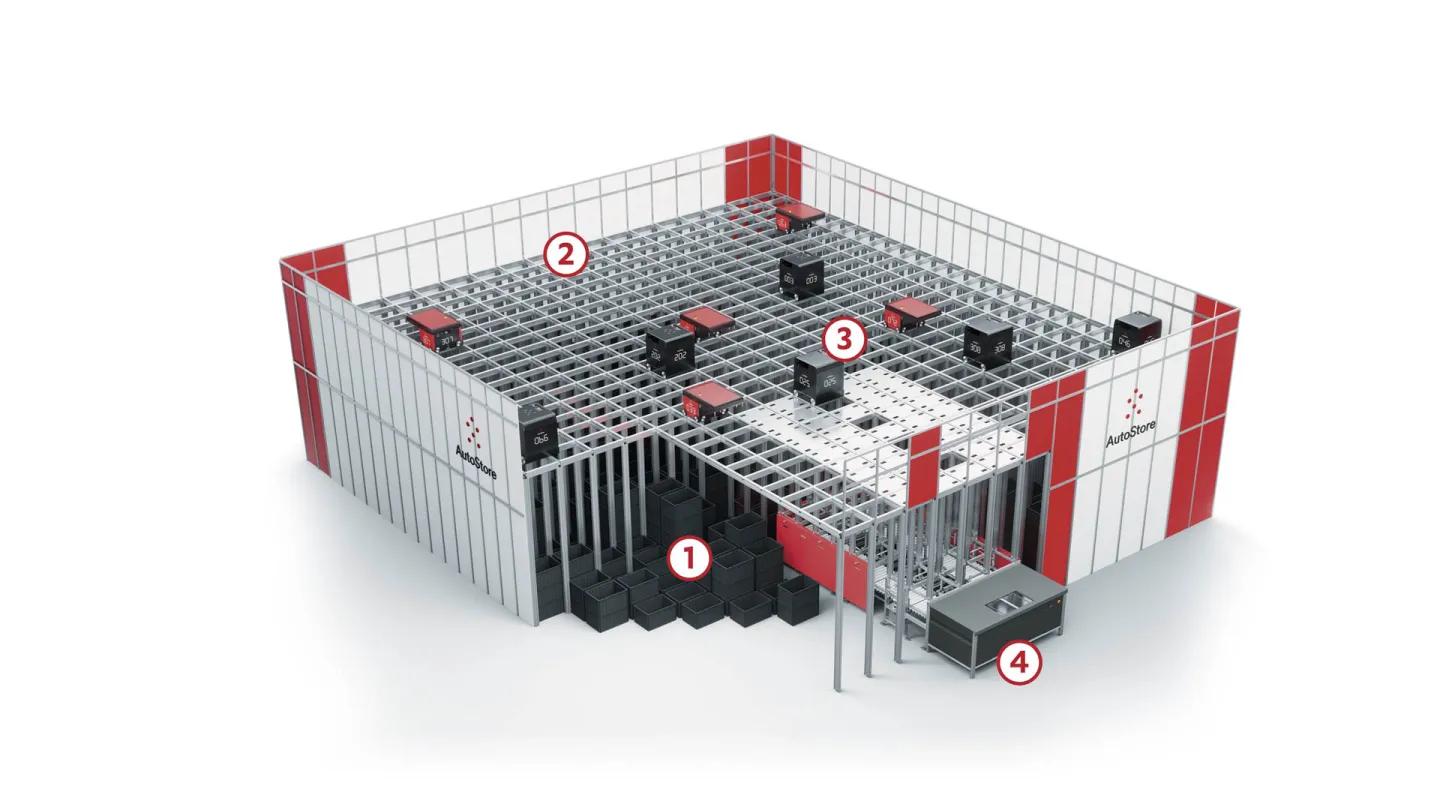

AutoStore® – The Ultimate Space Maker for Intralogistics

AutoStore® ist ein modernes und innovatives System zur automatischen Lagerung und Kommissionierung von Kleinteilen in Kunststoffbehältern, entwickelt von Jacob Hatteland Computer AS aus Norwegen. Das System entstand aus der Idee, Volumennutzungsgrad, Dynamik, Energieeffizienz, Erweiterbarkeit, Materialeinsatz und Anbindung von Kommissionierplätzen im Vergleich zu konventionellen Automatischen Kleinteilelagern (AKL) oder Shuttlesystemen zu optimieren.

Was sind die Vorteile mit dem AutoStore®-System?

Mit seiner kompakten Lagerlösung, die auf Gänge und Regale verzichtet, reduziert AutoStore® den Flächenbedarf um 75 %. Die Behälter werden übereinander in Stapeln auf den Boden gestellt. Über den Behälterstapeln ist ein Fahrschienensystem (Grid) montiert, auf dem Roboter fahren.

Unermüdlich nehmen sie Behälter auf, sortieren sie um und liefern sie zu den direkt angekoppelten Ports für Wareneingang und Kommissionierung. AutoStore® ist ein komplett modulares System, wobei die Anzahl der Roboter und Arbeitsstationen die Durchsatzleistung bestimmt.

Als offizieller Distributor bietet HÖRMANN Intralogistics AutoStore® mit dem dafür maßgeschneiderten WMS HiLIS AS als Generalunternehmer an. AutoStore® kann als Einzellösung installiert oder in ein Gesamt-Logistikkonzept integriert werden.

Für Kundenservice und Wartung steht das HÖRMANN Intralogistics Team an 365 Tagen rund um die Uhr für Sie zur Verfügung.

Ultrahohe Dichte und beste Verfügbarkeit

Mit dem bestechendem Lagerdichteverhältnis erreicht AutoStore® ultimative Raumeffizienz. Fast jede Gridform ist möglich und bestehende Gebäude können optimal genutzt werden. Durch den Einsatz mehrerer autonomer Roboter und angebundener Ports stellt AutoStore® ein verlässliches Lagersystem dar und überzeugt durch eine hohe Verfügbarkeit.

Red Line und Black Line

Die mehrfach prämierte AutoStore® Red Line erfüllt als extrem verfügbares und zuverlässiges System die Durchsatz- und Effizienzanforderungen bei geringem Platzangebot.

Für gesonderte Anforderungen steht die AutoStore® Black Line zur Verfügung und bietet mit zusätzlichen Funktionen, wie z. B. der austauschbaren Batterie, innovative Extraleistung.

Beide Linien können kombiniert werden, um ein optimales Systemdesign zu erreichen.

AutoStore® in Ihrem Lager – So funktioniert es:

- Bins (Behälter)

- Grid

- Roboter

- Ports (Kommissioniermodule)

-

Controller

- Warehouse-Management-System HiLIS AS

Bins (Behälter)

Das Maximalgewicht der stabilen und stapelbaren Behälter, die es in drei unterschiedlichen Höhen gibt, beträgt 35 kg. Zusätzlich ist eine antistatische ESD-Version erhältlich.

Grid

Die selbsttragende Aluminiumstruktur hält die Behälterstapel und führt auf den Schienen die Roboter. Modular kann das Grid in jeder beliebigen Form angeordnet werden.

Roboter

Die AutoStore®-Roboter bewegen sich durch ihre zwei über Eck angeordneten Räderpaare in zwei Fahrtrichtungen. So erreichen sie jede Position im Raster, um Behälter aufzunehmen, zu transportieren und abzusetzen.

Red Line Roboter

Mit ihren energieeffizienten Motoren und einem Rückgewinnungssystem sind sie unermüdlich im Einsatz. Wenn die Batterie schwach wird oder gerade keine Aufgaben zu erledigen sind, fahren die Red Line Roboter ihre am Rande des Grids gelegenen Ladestationen an.

Black Line Roboter

Die Black Line Roboter transportieren die Bins im Robotergehäuse und müssen nicht stationär aufgeladen werden. Durch die patentierte BattPack-Technologie kann die Black Line an den BattPack-Stationen jederzeit eine neue, vollgeladene Batterie aufnehmen.

| Red Line (SDG) | ERD LIN (DDG) | Black Line | |

|---|---|---|---|

| Länge /Zellenblock | 2 Zellen | 2 Zellen | 1,5 Zellen |

| Behälter-Typ | 220 mm · 330 mm · 425 mm | 220 mm · 330 mm · 425 mm | 220 mm · 330 mm · 425 mm |

| Beschleunigung | 0.8 m/s² | 0.8 m/s² | 1.4 m/s² |

| Geschwindigkeit | 3.1 m/s | 3.1 m/s | 4 m/s |

| Hubgeschwindigkeit | 2.5 m/s | 2.5 m/s | 2.5 m/s |

| Lärm | 71 dB | 71 dB | 66 dB |

| Batterie | AGM 2 x 12 V | AGM 2 x 12 V | BattPack |

Ports (Kommissioniermodule)

Die Ports können an allen Seiten des AutoStore®-Systems installiert und durch die Roboter unterbrechungsfrei versorgt werden. Die Ports werden für die effiziente Kommissionierung und Befüllung der Behälter genutzt.

Je nach Typ beträgt die Kommissionierleistung zwischen 160 und 650 Positionen pro Stunde.

CarouselPort – dreiarmiger Port

Der CarouselPort arbeitet mit drei rotierenden Armen, wobei jeder Arm mit einer Bin-Aufnahme ausgestattet ist. Eine Behälteraufnahme befindet sich im Zugriffsbereich des Bedieners und die zwei weiteren im Zugriffsbereich der Roboter, wodurch eine unterbrechungsfreie Belieferung möglich ist.

ConveyorPort – unkomplizierte Arbeitsstation

Der ConveyorPort verwendet ein Förderband, um die Bins zum Bediener zu bringen. Während ein Bin dem Bediener präsentiert wird, wird der zweite Bin oberhalb des Ports durch einen Roboter bereitgehalten.

RelayPort – schnellstmögliche Bin-Verfügbarkeit

Diese modulare Arbeitsstation besteht aus dem Kommissioniermodul Touch und Puffermodulen, genannt Tabs. Jede Kommissionierstation kann 3 bis 6 Tabs haben. Die Roboter sind in der Lage, die angewählten Positionen aus jeder Richtung zu erreichen.

SwingPort – vertikale Verbindung

Der SwingPort verwendet einen rotierenden Arm, um die Bins zum Bediener zu befördern. Während ein Bin dem Bediener präsentiert wird, befindet sich der zweite Bin in Warteposition.

Controller

Dieses Modul ist Kommandozentrum, Verkehrssteuerung und Datenbankverwaltung von AutoStore®.

Warehouse-Management-System HiLIS AS

Die AutoStore®-Steuerung führt autark die Transportaufträge für alle Roboter aus, kennt jedoch nicht den Inhalt der Behälter. Dafür hat HÖRMANN Intralogistics das übergeordnete Lagerverwaltungssystem HiLIS AS entwickelt. Dieses ist auf die Anforderungen von AutoStore® maßgeschneidert und wird direkt an die HOST-Systeme der Kunden angebunden.

HiLIS AS stellt die Wareneingangs- und Kommissionierinformationen an den Ports zur Verfügung, bildet alle Bedienerfunktionalitäten ab und ermöglicht die Bedienereingriffe.

Wie hoch sind bei einem neuen AutoStore® die Kosten?

Aufgrund der zahlreichen Vorteile für effizienteres Kommissionieren und Steuerung Ihrer Intralogistik amortisieren sich mit AutoStore® die Investitionskosten schon nach kurzer Zeit. Entlasten Sie Ihre Mitarbeiter und steigern Sie Ihre Effizienz mit einer maßgeschneiderten Lösung von HÖRMANN Intralogistics.

HÖRMANN Intralogistics und AutoStore® – Höchstleistung auf kleinstem Raum

AutoStore® wird nach Ihren Anforderungen auf Basis einer Simulation maßgeschneidert konfiguriert. Ihre Mengengerüste, Artikel-/Auftragsstruktur und Leistungsanforderungen bestimmen die Größe, die Anzahl der Roboter und die Anzahl der Kommissioniermodule.

AutoStore® eignet sich sowohl für Anforderungen mit geringer Leistung und großer Stellplatzkapazität als auch für hochdynamische Anforderungen mit mehreren Tausend Ein- und Auslagerungen pro Stunde.

AutoStore® – The Ultimate Space Maker for Intralogistics

AutoStore® ist ein modernes und innovatives System zur automatischen Lagerung und Kommissionierung von Kleinteilen in Kunststoffbehältern, entwickelt von Jacob Hatteland Computer AS aus Norwegen. Das System entstand aus der Idee, Volumennutzungsgrad, Dynamik, Energieeffizienz, Erweiterbarkeit, Materialeinsatz und Anbindung von Kommissionierplätzen im Vergleich zu konventionellen Automatischen Kleinteilelagern (AKL) oder Shuttlesystemen zu optimieren.

Was sind die Vorteile mit dem AutoStore®-System?

Mit seiner kompakten Lagerlösung, die auf Gänge und Regale verzichtet, reduziert AutoStore® den Flächenbedarf um 75 %. Die Behälter werden übereinander in Stapeln auf den Boden gestellt. Über den Behälterstapeln ist ein Fahrschienensystem (Grid) montiert, auf dem Roboter fahren.

Unermüdlich nehmen sie Behälter auf, sortieren sie um und liefern sie zu den direkt angekoppelten Ports für Wareneingang und Kommissionierung. AutoStore® ist ein komplett modulares System, wobei die Anzahl der Roboter und Arbeitsstationen die Durchsatzleistung bestimmt.

Als offizieller Distributor bietet HÖRMANN Intralogistics AutoStore® mit dem dafür maßgeschneiderten WMS HiLIS AS als Generalunternehmer an. AutoStore® kann als Einzellösung installiert oder in ein Gesamt-Logistikkonzept integriert werden.

Für Kundenservice und Wartung steht das HÖRMANN Intralogistics Team an 365 Tagen rund um die Uhr für Sie zur Verfügung.

Ultrahohe Dichte und beste Verfügbarkeit

Mit dem bestechendem Lagerdichteverhältnis erreicht AutoStore® ultimative Raumeffizienz. Fast jede Gridform ist möglich und bestehende Gebäude können optimal genutzt werden. Durch den Einsatz mehrerer autonomer Roboter und angebundener Ports stellt AutoStore® ein verlässliches Lagersystem dar und überzeugt durch eine hohe Verfügbarkeit.

Red Line und Black Line

Die mehrfach prämierte AutoStore® Red Line erfüllt als extrem verfügbares und zuverlässiges System die Durchsatz- und Effizienzanforderungen bei geringem Platzangebot.

Für gesonderte Anforderungen steht die AutoStore® Black Line zur Verfügung und bietet mit zusätzlichen Funktionen, wie z. B. der austauschbaren Batterie, innovative Extraleistung.

Beide Linien können kombiniert werden, um ein optimales Systemdesign zu erreichen.

AutoStore® in Ihrem Lager – So funktioniert es:

- Bins (Behälter)

- Grid

- Roboter

- Ports (Kommissioniermodule)

-

Controller

- Warehouse-Management-System HiLIS AS

Bins (Behälter)

Das Maximalgewicht der stabilen und stapelbaren Behälter, die es in drei unterschiedlichen Höhen gibt, beträgt 35 kg. Zusätzlich ist eine antistatische ESD-Version erhältlich.

Grid

Die selbsttragende Aluminiumstruktur hält die Behälterstapel und führt auf den Schienen die Roboter. Modular kann das Grid in jeder beliebigen Form angeordnet werden.

Roboter

Die AutoStore®-Roboter bewegen sich durch ihre zwei über Eck angeordneten Räderpaare in zwei Fahrtrichtungen. So erreichen sie jede Position im Raster, um Behälter aufzunehmen, zu transportieren und abzusetzen.

Red Line Roboter

Mit ihren energieeffizienten Motoren und einem Rückgewinnungssystem sind sie unermüdlich im Einsatz. Wenn die Batterie schwach wird oder gerade keine Aufgaben zu erledigen sind, fahren die Red Line Roboter ihre am Rande des Grids gelegenen Ladestationen an.

Black Line Roboter

Die Black Line Roboter transportieren die Bins im Robotergehäuse und müssen nicht stationär aufgeladen werden. Durch die patentierte BattPack-Technologie kann die Black Line an den BattPack-Stationen jederzeit eine neue, vollgeladene Batterie aufnehmen.

| Red Line (SDG) | ERD LIN (DDG) | Black Line | |

|---|---|---|---|

| Länge /Zellenblock | 2 Zellen | 2 Zellen | 1,5 Zellen |

| Behälter-Typ | 220 mm · 330 mm · 425 mm | 220 mm · 330 mm · 425 mm | 220 mm · 330 mm · 425 mm |

| Beschleunigung | 0.8 m/s² | 0.8 m/s² | 1.4 m/s² |

| Geschwindigkeit | 3.1 m/s | 3.1 m/s | 4 m/s |

| Hubgeschwindigkeit | 2.5 m/s | 2.5 m/s | 2.5 m/s |

| Lärm | 71 dB | 71 dB | 66 dB |

| Batterie | AGM 2 x 12 V | AGM 2 x 12 V | BattPack |

Ports (Kommissioniermodule)

Die Ports können an allen Seiten des AutoStore®-Systems installiert und durch die Roboter unterbrechungsfrei versorgt werden. Die Ports werden für die effiziente Kommissionierung und Befüllung der Behälter genutzt.

Je nach Typ beträgt die Kommissionierleistung zwischen 160 und 650 Positionen pro Stunde.

CarouselPort – dreiarmiger Port

Der CarouselPort arbeitet mit drei rotierenden Armen, wobei jeder Arm mit einer Bin-Aufnahme ausgestattet ist. Eine Behälteraufnahme befindet sich im Zugriffsbereich des Bedieners und die zwei weiteren im Zugriffsbereich der Roboter, wodurch eine unterbrechungsfreie Belieferung möglich ist.

ConveyorPort – unkomplizierte Arbeitsstation

Der ConveyorPort verwendet ein Förderband, um die Bins zum Bediener zu bringen. Während ein Bin dem Bediener präsentiert wird, wird der zweite Bin oberhalb des Ports durch einen Roboter bereitgehalten.

RelayPort – schnellstmögliche Bin-Verfügbarkeit

Diese modulare Arbeitsstation besteht aus dem Kommissioniermodul Touch und Puffermodulen, genannt Tabs. Jede Kommissionierstation kann 3 bis 6 Tabs haben. Die Roboter sind in der Lage, die angewählten Positionen aus jeder Richtung zu erreichen.

SwingPort – vertikale Verbindung

Der SwingPort verwendet einen rotierenden Arm, um die Bins zum Bediener zu befördern. Während ein Bin dem Bediener präsentiert wird, befindet sich der zweite Bin in Warteposition.

Controller

Dieses Modul ist Kommandozentrum, Verkehrssteuerung und Datenbankverwaltung von AutoStore®.

Warehouse-Management-System HiLIS AS

Die AutoStore®-Steuerung führt autark die Transportaufträge für alle Roboter aus, kennt jedoch nicht den Inhalt der Behälter. Dafür hat HÖRMANN Intralogistics das übergeordnete Lagerverwaltungssystem HiLIS AS entwickelt. Dieses ist auf die Anforderungen von AutoStore® maßgeschneidert und wird direkt an die HOST-Systeme der Kunden angebunden.

HiLIS AS stellt die Wareneingangs- und Kommissionierinformationen an den Ports zur Verfügung, bildet alle Bedienerfunktionalitäten ab und ermöglicht die Bedienereingriffe.

Wie hoch sind bei einem neuen AutoStore® die Kosten?

Aufgrund der zahlreichen Vorteile für effizienteres Kommissionieren und Steuerung Ihrer Intralogistik amortisieren sich mit AutoStore® die Investitionskosten schon nach kurzer Zeit. Entlasten Sie Ihre Mitarbeiter und steigern Sie Ihre Effizienz mit einer maßgeschneiderten Lösung von HÖRMANN Intralogistics.

HÖRMANN Intralogistics und AutoStore® – Höchstleistung auf kleinstem Raum

AutoStore® wird nach Ihren Anforderungen auf Basis einer Simulation maßgeschneidert konfiguriert. Ihre Mengengerüste, Artikel-/Auftragsstruktur und Leistungsanforderungen bestimmen die Größe, die Anzahl der Roboter und die Anzahl der Kommissioniermodule.

AutoStore® eignet sich sowohl für Anforderungen mit geringer Leistung und großer Stellplatzkapazität als auch für hochdynamische Anforderungen mit mehreren Tausend Ein- und Auslagerungen pro Stunde.

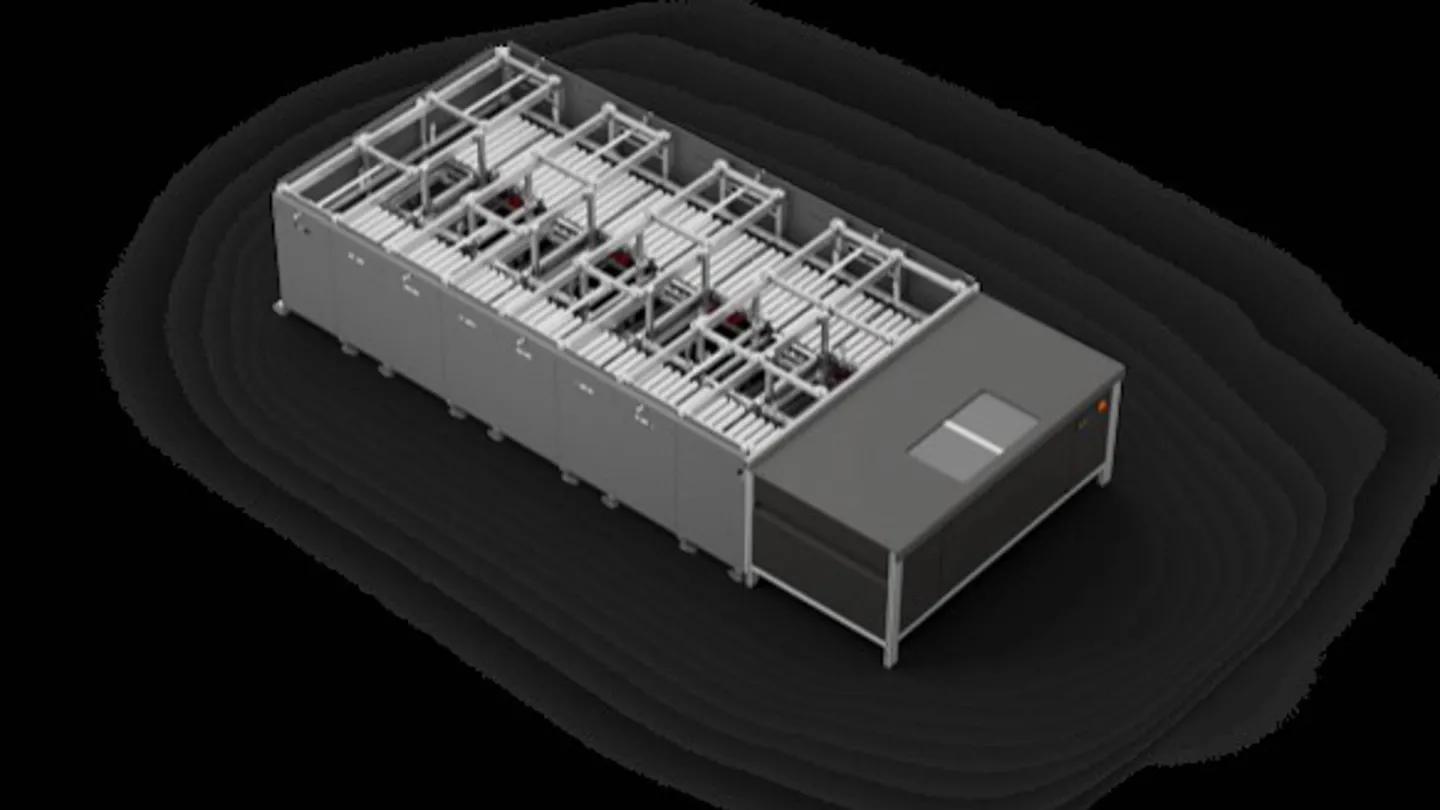

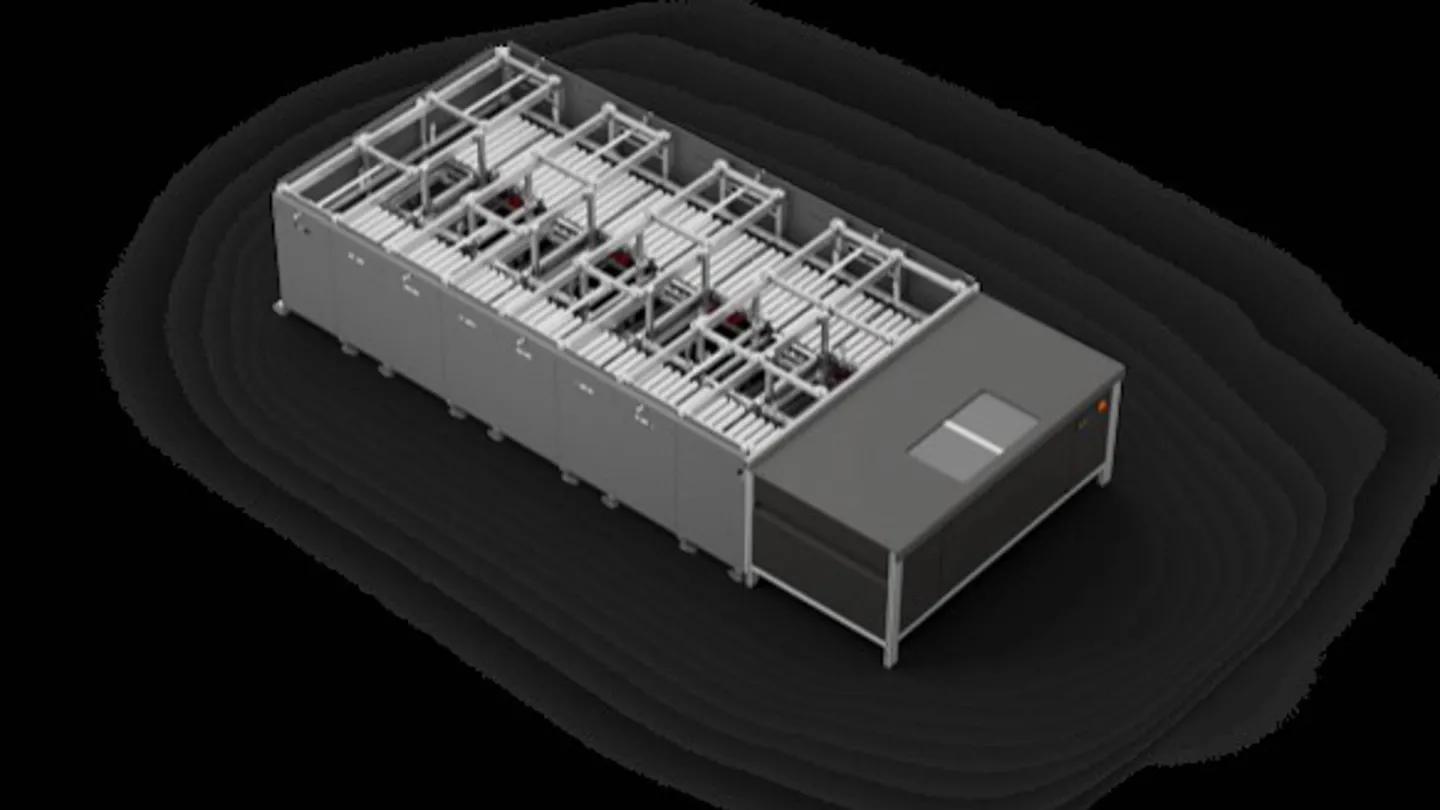

Conveyors - Customised, innovative conveyor technology

HÖRMANN Klatt Conveyors from Neumarkt am Wallersee in Austria has been an important partner for companies worldwide in the field of conveyor systems for many years. Our portfolio includes a wide range of standardised conveyor technologies for a variety of applications, as well as special custom solutions.

We design and implement the best and most economical conveyor solutions

- Consulting and planning

- Manufacturing and pre-assembly

- Project management and execution

- Assembly and commissioning

- Service and maintenance

The Hawle Austria Group produces and distributes heavy-duty valves worldwide. These products, which have been under development for generations, are used in residential water management from source to home.

Precision, perfection, passion - that's what HÖRMANN Klatt Conveyors stands for. Our Made in Austria conveyor technology is known throughout Europe and covers the transport of pallets, packages, boxes and lumber stacks. We put great importance on implementing individual solutions perfectly - from development to construction and on-site assembly.

Our customers appreciate our professional project management, competence, high-quality product solutions and handshake quality. That's why HÖRMANN Klatt Conveyors is the best partner for you when it comes to conveyor, storage and systemisation technology.

HÖRMANN Klatt Conveyors leaflet 2023

Individual conveyor systems

- Project timeline - from consulting to customer service

- Innovative special conveyor systems - from pallet to film transport setups

- Corporate culture and sustainability