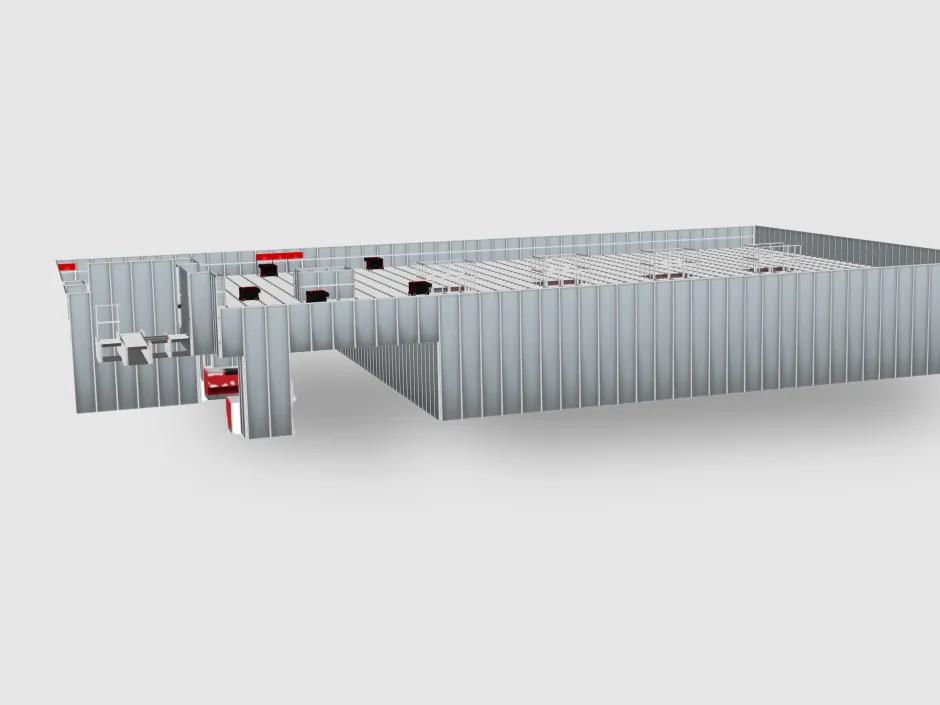

Hörmann Intralogistics takes on pioneering role with automation concept for Siemens

convey + lift magazine

Brochures, white papers, logos, images

Downloads

Downloads from HÖRMANN Intralogistics

Download brochures, white papers, logos and images quickly and easily here to find out more about our innovative logistics solutions and optimize your intralogistics.

Brochures

Image brochure - Your general contractor for intralogistics

HiLIS - Integrated, modular warehouse management system

Corrugated cardboard - We bring dynamism to the industry

Klatt Conveyors - your innovative partner for individual conveyor technology solutions

Paper rolls - high-bay warehouse in the USA

Whitepaper, flyer

Whitepaper

E-commerce & logistics systems of the future - micro-fulfillment

Whitepaper

Fulfillment strategies in online food retail

Logos, Images

.zip file logos

.zip file images

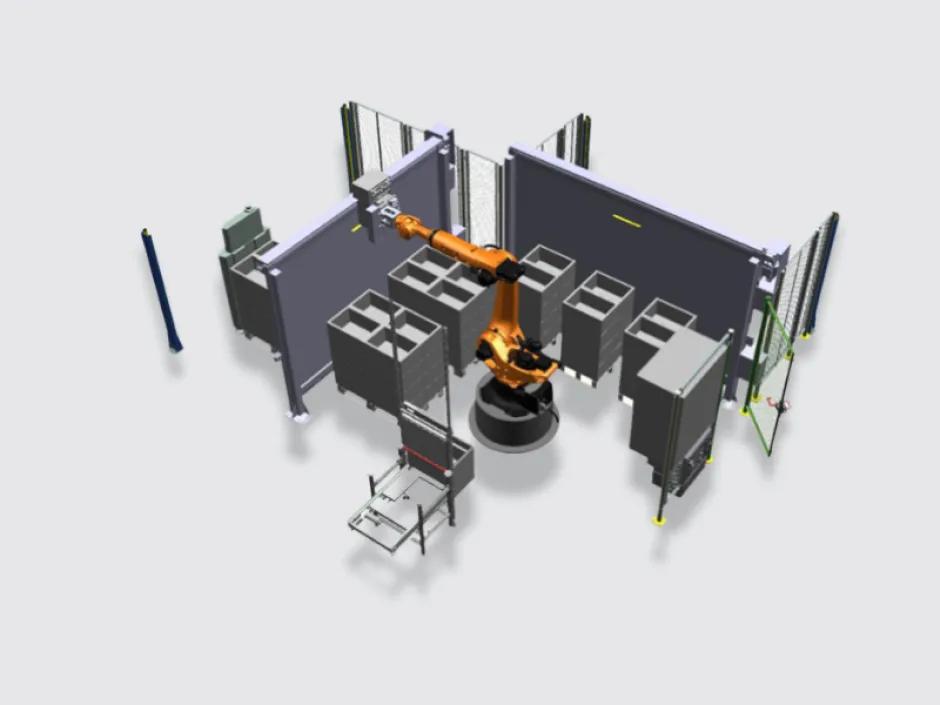

High density and dynamics

Small parts warehouse

Customised small parts storage solutions with AutoStore®, miniload, trays or shuttle

Maximize your storage capacity and efficiency with our specialized small parts storage systems. Whether light or heavy goods, individually or in containers, cartons or trays - we offer customized AutoStore® systems, small parts warehouses with RGB as well as tray or shuttle warehouses that are perfectly tailored to your requirements.

Our solutions are suitable for classic storage functions, buffer storage, shipping warehouses, production supply and as a state-of-the-art picking system. Rely on our expertise to optimize your logistics processes and increase your competitiveness.

The benefits at a glance

- Saving space: Optimized use of storage space thanks to compact storage

- Increased efficiency: Automated processes increase throughput and reduce processing time

- Flexibility: Adaptable to different goods sizes and weights

- Cost reduction: reducing manual intervention lowers labour costs and increases process reliability

- Goods protection: gentle handling techniques minimize the risk of damage

"With our experience as a general contractor in various industries and the customized warehouse management system HiLIS, we design and implement an individual, efficient and future-proof small parts warehouse for you."

ROBERT HEINZ | AUTOSTORE DIVISION MANAGER

HÖRMANN INTRALOGISTICS SOLUTIONS GMBH

What are small parts warehouses?

Small parts warehouses are specialized forms of storage designed for the efficient storage and provision of small goods and components, often in racks with small load carriers, boxes or containers. They are characterized by a high storage density and efficient use of space, often with automated systems for fast and clear storage and retrieval.

Dynamic storage and picking

Picking is standardized according to the "goods to person" principle. Ergonomically optimized provision of goods to the picker using storage and retrieval machines, conveyor technology and robots enables the picker to work with high picking performance and a low error rate.

The picker is supported by various modern technologies, such as picking robots, driverless transport vehicles, "pick-by-light", "put-to-light", "pick-by-voice", handheld terminals, PC terminals and others.

Online interfaces to various parcel service providers with label printing for each package are provided by our customized HiLIS Warehouse Management System.

All services at a glance

Shelving systems

- Silo constructions for small parts warehouses, trays and shuttles

- Built-in shelving constructions for small parts warehouses, trays and shuttles

- AutoStore aluminum grids

Cargo

- Containers

- Cartons

- Tables

- and many more

Storage type

- Single-deep or multi-deep with AKL, trays and shuttle

- Up to 18 levels of container stacks with AutoStore

Load handling attachments for AKL

- Combination telescope

- Pulling device

- Gripping device

Additional systems & robotics

- Pick-by-robot for KLT or piece picking

- Driverless transport systems for supply from other storage areas

- Pick-by-light/pick-to-light/pick-by-voice

- Connecting conveyor technology

Contact us

HÖRMANN Intralogistics also implements highly dynamic small parts warehouses with supplementary conveyor and picking technology as well as robotics.

We bring all our expertise to every project and ensure tailor-made overall solutions for your economically successful future.

Flexible, cost-saving, damage-avoiding

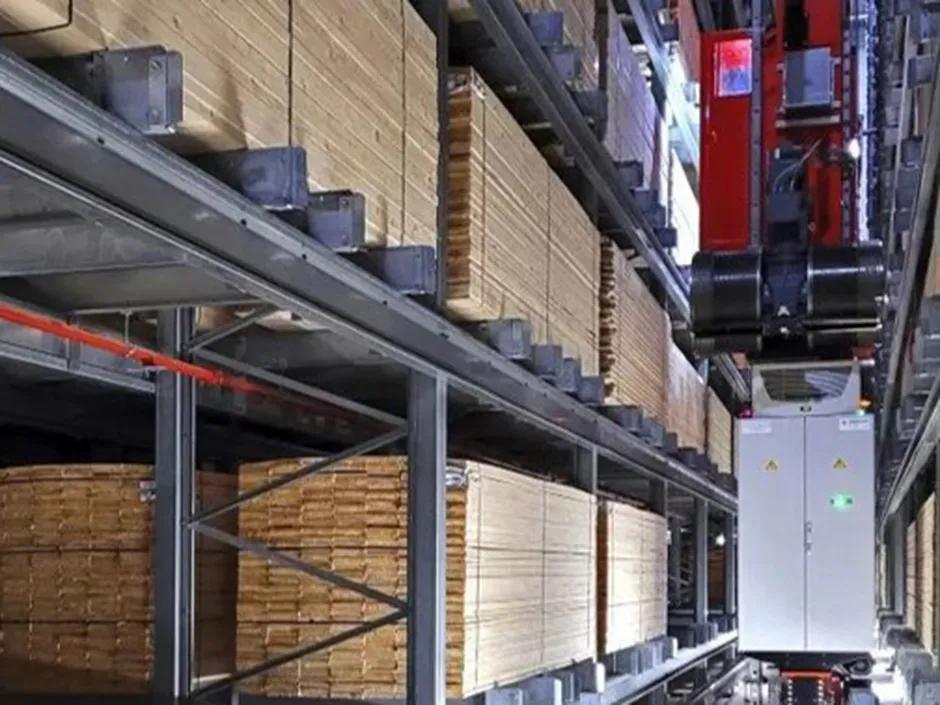

Automatic timber or heavy-duty storage systems

Specialized high-bay warehouse solutions for heavy and bulky goods

For heavy and bulky goods, we develop and implement high-bay warehouse solutions with tailor-made storage and retrieval and conveyor technology. This allows goods with a wide range of dimensions and weights to be stored in a space-saving and gentle manner using sophisticated storage strategies. At the customer's request, we also integrate the automatic just-in-time connection to production and dispatch provision.

The advantages at a glance

- Decoupling of production processes, pre-processing and finishing in order to maximize flexibility, Customer orientation and production performance

- On-demand packaging and provision of timber or other heavy-duty packages for customer shipping and in-house further processing in production

- Increased and plannable loading performance

- Reduction of manual processes

- Fully automated, multi-stage packaging and transport preparation to secure the products themselves and to ensure an efficient and gentle loading process

- The gentle, automatic conveying and handling technology prevents damage to the products and therefore avoids the costs of complaints and replacement deliveries

- Consistent use of plastic chain conveyor technology made from high-quality, lubricant-free plastic for maximum protection of the product during in-house transport

All about timber or heavy-duty intralogistics

""The all-in-one concept from HÖRMANN Intralogistics has enabled us to revolutionize our logistics processes. The designed software control, sensor technology, innovative conveyor technology and seamless integration into our existing processes increase our efficiency and competitiveness. We are delighted with the possibilities offered by this new system."

STEFAN HIERZENBERGER | HEAD OF GROUP LOGISTICS,

MAYR-MELNHOF WOOD

What makes timber and heavy-duty warehouses so special?

Automatic timber or heavy-duty warehouses enable the efficient and space-saving storage of heavy goods thanks to customized, fully automated storage and retrieval technologies that minimize manual intervention. Gentle conveying technologies protect the goods from damage and integrate seamlessly into production and shipping processes, increasing efficiency and reducing costs.

How it works

The state-of-the-art intralogistics solution for timber and heavy goods includes multi-aisle high-bay warehouses as well as connecting, individually developed, gentle modular belt conveyor technology for order-related sequencing, packaging, stacking and route-specific provision with subsequent semi-automatic truck loading in the loading hall.

The conveyor technology transports the heavy-duty packages from the production area to the high-bay warehouse. Here, the load units are temporarily stored and, depending on the order, either loaded onto trucks for internal or external customers for further processing. For truck loading, the parcels are put together in the correct sequence and route, packed and stacked if required. A distribution trolley then transports the heavy-duty parcels to the respective staging lane next to trailers in the loading hall.

Intelligent intralogistics strategies with the HiLIS product portfolio

Warehouse management, system control, system visualization and truck loading are carried out using the tried-and-tested HÖRMANN Intralogistics HiLIS, which communicates with the customer system via an interface.

Reference film

The wood logistics movie: Intralogistics for the wood industry - at Mayr Melnhof Holz in Leoben

Intralogistics for the timber industry - at Mayr Melnhof Holz in Leoben

Contact us

Manage & optimize warehouse

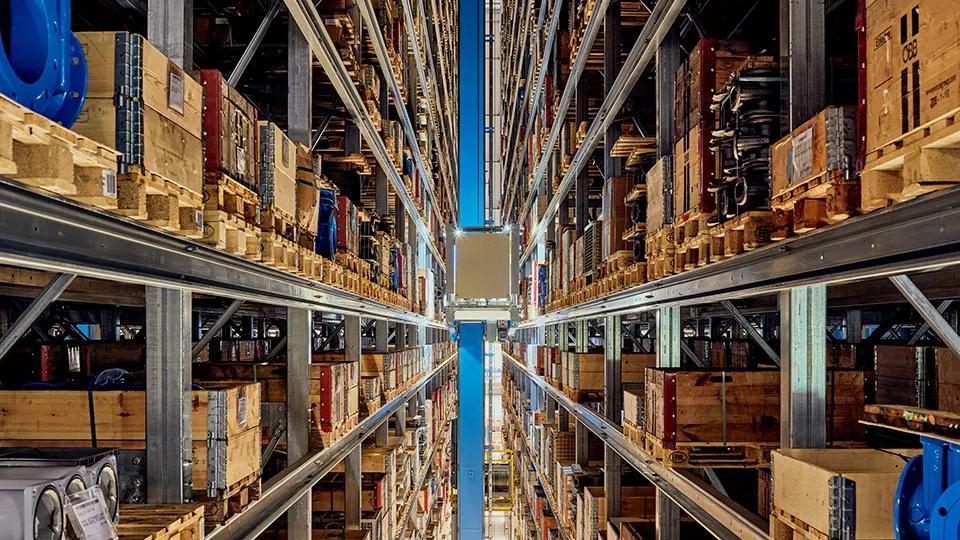

High-bay warehouse: customized and highly available

Compact and automated storage solutions

Maximize your storage capacity and efficiency with our tailor-made high-bay storage systems. The solutions offer compact storage in a small space, ideal for companies that want to both save space and optimize their processes. With fully automated storage and retrieval, we guarantee a smooth process from goods receipt to dispatch preparation.

Our expertise includes the development of SRM-based high-bay warehouses, both as in-house and silo systems. We also offer special high-bay warehouses for rolls, sensitive corrugated cardboard, wood and heavy goods. Rely on experience and optimize your logistics with our advanced storage solutions.