Reference Mayr-Melnhof Holz

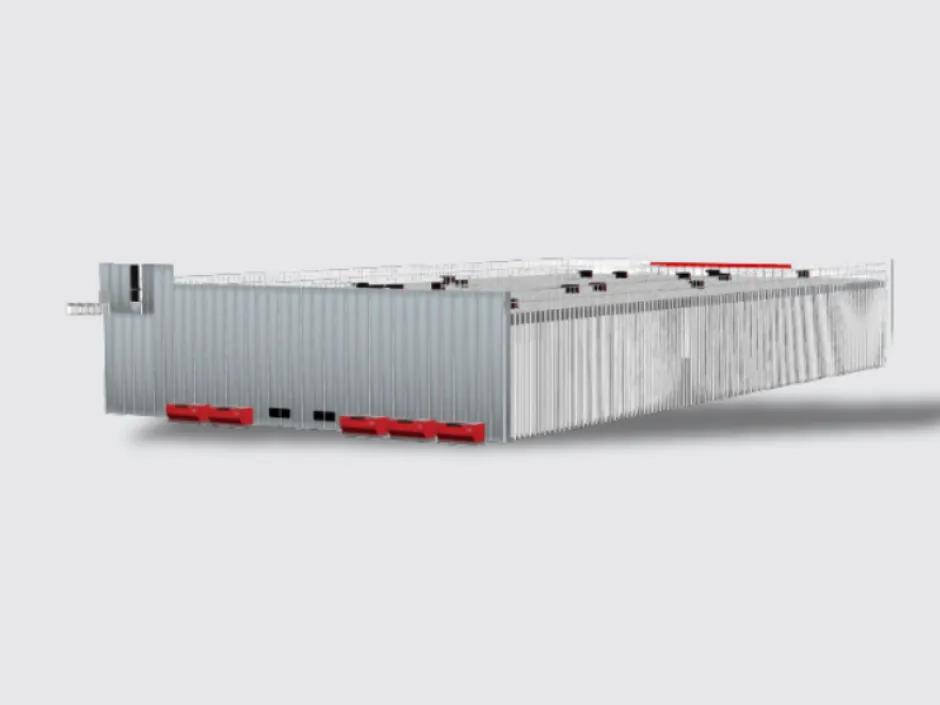

Automated high-bay warehouse and loading hall for timber

HÖRMANN Intralogistics has implemented a pioneering intralogistics solution for the Mayr-Melnhof Holz Group in Leoben, based on the functional specifications of logistics planner Xvise from Lauterbach (Austria), which makes the long-established company a pioneer in the wood processing industry. The combination of an automated, three-aisle high-bay warehouse with innovative conveyor technology, a complex packaging line and, for the first time, a semi-automatic truck loading hall sets new standards in timber logistics.

The concept

Automatic high-bay warehouse with customized conveyor technology for Mayr-Melnhof Holz in Leoben

The high-bay warehouse (HRL) as well as the logistics and loading hall were and the loading hall were built on an existing site next to the existing production halls of the sawmill and directly adjacent to the newly built high-performance re-sorting and planing plant and the new high-tech cross laminated timber plant. The conveyor system transports the timber packages from the sorting and planing mill to the high-bay warehouse. In the 3-aisle high-bay warehouse, the timber packages are temporarily stored and, depending on the order, either loaded onto trucks for internal and external customers or transferred to the cross-laminated timber plant for further processing. For truck loading, the sawn timber packages are put together in the correct sequence and route, packed and stacked if required. A distribution wagon then transports the heavy-duty packages to the respective staging lane next to trailers in the loading hall.

Flexible and gentle material flow with innovative modular belt conveyor technology

The load units are bundled packages of sawn timber measuring up to 5.2 m long, 1.27 m wide and 1.30 m high, weighing up to 3.200 kg. HÖRMANN Intralogistics uses innovative modular belt conveyor technology made of high-quality, lubricant-free plastic with integrated transport rollers to transport the packages safely and gently on the conveyor system. The packages can be transported on these with or without squared timber. All packages undergo a weight and contour check when they are transferred from the sorting and planing plant.

On arrival from the sorting and planing mill, the timber packages are automatically picked up, checked and transported to the pre-zone of the high-bay warehouse. At the storage infeed, packages up to 4.2 m / 2.7 t are positioned centrally to the storage and retrieval machine (SRM) according to their lengths and transferred by the SRM to 3-deep rack storage locations.

Order-related sequencing and gantry robot station for stacks of 3 and 4 packages

The timber packages are then retrieved in sequence and to the exact route. During this process step, there are further sorting options directly on the conveyor system. For the most part, the packages are wrapped fully automatically at the customer's request, underlaid with squared timber by a robot and strapped. After automatic labeling, the parcels are stacked.

This takes place in the hall pre-zone, where up to four parcels can be put together by a straddle stacker to form a lift for truck loading. Two parcels next to each other and two parcels on top of each other form this hub.

In the high-bay warehouse's secondary storage zone, retrieval slots have also been included in every aisle. Packages of sawn timber are retrieved here and fed to the cross laminated timber plant via a distribution trolley.

Intelligent intralogistics strategies with the warehouse management system HiLIS

Warehouse management, System control and system visualization is carried out with the proven HÖRMANN Intralogistics Warehouse Management System HiLIS, which communicates with the customer system via an interface. With 24/7 operating times, HiLIS continuously receives retrieval and storage orders for the items to be loaded via an interface from the on-site HOST.

Objectives and challenges of the project:

- Efficient and asynchronous supply of three areas: External customers, MMH Geishorn site, cross laminated timber production

- Lubricating oil-free transport of the living natural product with board length differences

- Packages with and without scantlings as well as foiling on the same packaging line

- Largely automated, capacity-optimized truck loading

Facts & figures

| High-bay warehouse | Packing line & truck loading hall |

|---|---|

|

|

"The all-in-one concept from HÖRMANN Intralogistics has enabled us to revolutionize our logistics processes. The designed software control, sensor technology, innovative conveyor technology and seamless integration into our existing processes increase our efficiency and competitiveness. We are delighted with the possibilities offered by this new system."

Stefan Hierzenberger

Head of Group Logistics, MMH

About MMH & Hörmann Intralogistics

About MMH

Mayr-Melnhof Holz Holding AG, headquartered in Leoben, was founded in 1850 and is one of the leading European companies in the sawn timber and wood processing sectors. Around 1,630 people are employed at nine locations. As a driving force in the timber industry, market leader in the glulam segment and a driving force in the advance in the production of cross-laminated timber, the building and construction material of the future, the long-established company relies on advanced, efficient plant solutions for the expansion and modernization of its plants.

About Hörmann Intralogistics

Mayr-Melnhof Holz Holding AG, headquartered in Leoben, was founded in 1850 and is one of the leading European companies in the sawn timber and wood processing sectors. Around 1,630 people are employed at nine locations. As a driving force in the timber industry, market leader in the glulam segment and a driving force in the advance in the production of cross-laminated timber, the building and construction material of the future,the long-established company relies on advanced, efficient plant solutions for the expansion and modernization of its plants.

Reference film

The wood logistics movie: Intralogistics for the wood industry - at Mayr Melnhof Holz in Leoben

Timber-Intralogistics at Mayr-Melnhof Holz in Leoben

Contact us

Do you see yourself in the MMH story with challenges and possible solutions for your own business? Get in touch with our project planning experts without obligation. We will give you an assessment of your current and optimized material flow, automation options and an initial target price.